Posted By: davefarmer

Boom design advice? - 11/22/06 05:22 AM

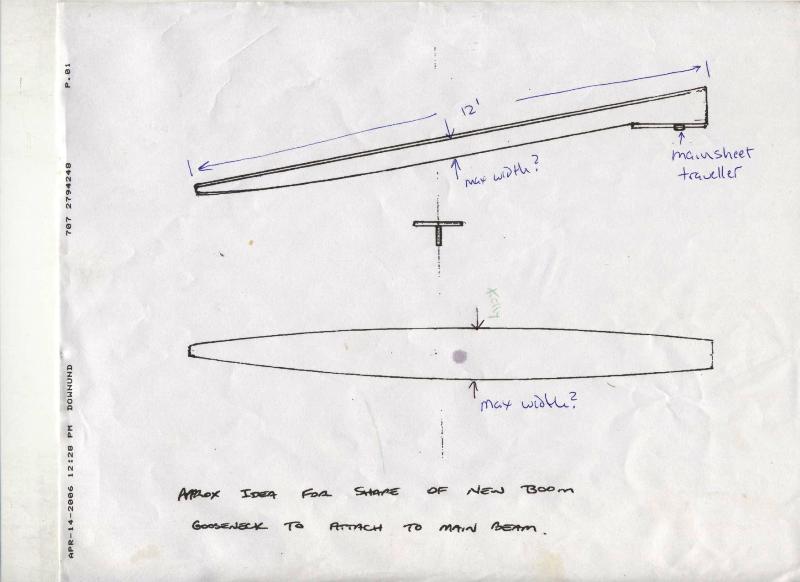

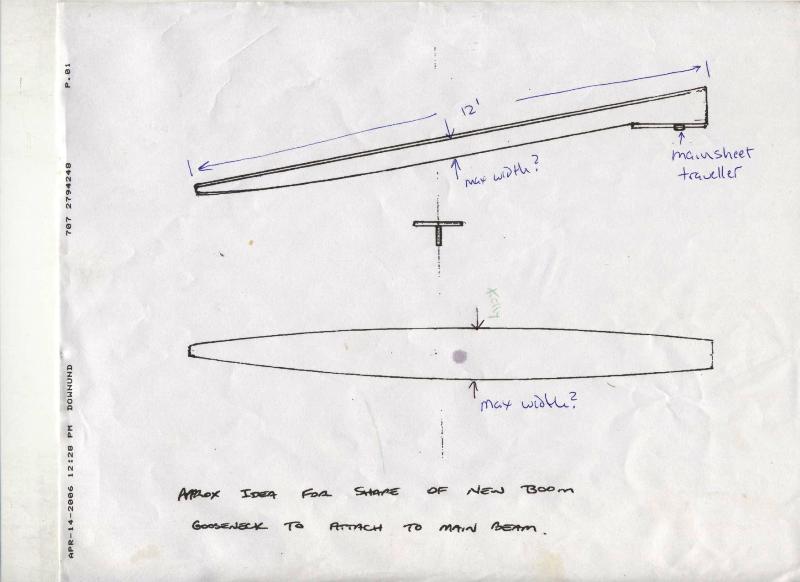

Flight Risk needs a new booom, and I'm contemplating a T

shaped design similar to ones seen on ORMA 60s (see attached sketch). The original boom (see next pic) had to be lengthened when it's gooseneck was moved down 22" from its original position on the wingmast, to the main crossbeam, just below the maststep. This changed the angle of the underside mainsheet traveller (ala 18 meter square) that serves as vang.

The original boom was also strengthened (w/ a carbon tube bogged and slipped inside) at the same time it was lengthened, and still there was noticible flexing. So the compression forces seem big. (The main is an EP squaretop with a 34' luff and 11' foot). So now the boom's too heavy as well.

So the proposed plan is to vacuum bag carbon uni to the flat surfaces of a couple of Sitka spruce planks, cut to profiles similar to the sketch, screw 'em together in the T cross section, hi density fillet either side of the joint, layer of 2" tape followed by a 4" tape, tape all three edges.

So it's advice on the details I'm asking for.

Thickness of the boards (.75", 1", 1.25")?

Width of boards @ widest point (8", 10", 12")?

Weight of carbon uni (6 oz)?

Does carbon come in a woven tape (what weights)? S glass?

Are the tape widths proposed for joint reinforcements appropriate/sufficient?

I think the design offers a lot of strength and pretty light weight, and I think there's less than $500 in materials. But I'm open to other affordable ideas. I can get a 2.25" x 10' or 12' carbon spin pole blank for around $450 retail, but I still need to modify it for the underside traveller. And is a pole like that stiff enough for this application?

Other souces for carbon poles? Other concepts entirely? Baseless crticism and ridicule?

Thanks!

Dave

shaped design similar to ones seen on ORMA 60s (see attached sketch). The original boom (see next pic) had to be lengthened when it's gooseneck was moved down 22" from its original position on the wingmast, to the main crossbeam, just below the maststep. This changed the angle of the underside mainsheet traveller (ala 18 meter square) that serves as vang.

The original boom was also strengthened (w/ a carbon tube bogged and slipped inside) at the same time it was lengthened, and still there was noticible flexing. So the compression forces seem big. (The main is an EP squaretop with a 34' luff and 11' foot). So now the boom's too heavy as well.

So the proposed plan is to vacuum bag carbon uni to the flat surfaces of a couple of Sitka spruce planks, cut to profiles similar to the sketch, screw 'em together in the T cross section, hi density fillet either side of the joint, layer of 2" tape followed by a 4" tape, tape all three edges.

So it's advice on the details I'm asking for.

Thickness of the boards (.75", 1", 1.25")?

Width of boards @ widest point (8", 10", 12")?

Weight of carbon uni (6 oz)?

Does carbon come in a woven tape (what weights)? S glass?

Are the tape widths proposed for joint reinforcements appropriate/sufficient?

I think the design offers a lot of strength and pretty light weight, and I think there's less than $500 in materials. But I'm open to other affordable ideas. I can get a 2.25" x 10' or 12' carbon spin pole blank for around $450 retail, but I still need to modify it for the underside traveller. And is a pole like that stiff enough for this application?

Other souces for carbon poles? Other concepts entirely? Baseless crticism and ridicule?

Thanks!

Dave

![[Linked Image]](http://www.catsailor.com/bb_files/91194-baby_incoming.jpg)

![[Linked Image]](http://www.catsailor.com/bb_files/91254-Composite_boom.gif)

![[Linked Image]](http://www.catsailor.com/bb_files/91299-Carbon_alu_equivalence.gif)

![[Linked Image]](http://www.catsailor.com/bb_files/91321-lightweight_timber_spar_pic_1_of_4.gif)

![[Linked Image]](http://www.catsailor.com/bb_files/91321-lightweight_timber_spar_pic_2_of_4.gif)

![[Linked Image]](http://www.catsailor.com/bb_files/91321-lightweight_timber_spar_pic_3_of_4.gif)

![[Linked Image]](http://www.catsailor.com/bb_files/91321-lightweight_timber_spar_pic_4_of_4.gif)