Catsailor.com extending hulls?

Posted By: Dirk extending hulls? - 12/20/06 08:20 AM

I intend to lenghten the hulls of an old SC20. Basically I only want to extend the bow by changing the shape to a more modern straight bow but keep the original hulls and structure like it is. So the principle would be glueing foam onto the existing structure, shaping it and cover with carbon fibres than. I think of an overall hull lenght extension of 1-2 feet with most volume added to the lower part of the currently eliptical shape as it is intended to end up with a straight bow. As the sctructural integrity of the hulls is not touched, this bow extension would only have to withstands the forces from the water/waves.

I wonder if anyone has done this before and is willing to share his knowledge which would be highly appreciated!

Kind regards

Dirk

Posted By: Jalani Re: extending hulls? - 12/20/06 09:32 AM

Cool bit of Photoshopping Dirk!

Sorry I can't offer any advice with your project though - other than to ask: Why? <img src="http://www.catsailor.com/forums/images/graemlins/smile.gif" alt="" />

Posted By: Erez Re: extending hulls? - 12/20/06 09:40 AM

Posted By: Dirk Re: extending hulls? - 12/20/06 10:02 AM

@John:

two reasons

1. functional

the SC20 has a nosediving tendency which is reflected in the fact that the boat nowadays only exist in a 2 feet longer version (ARC22). I think I don't have to raise the benefits of more volume in the bow, specially when its increasing the waterline length... as intended. curently the boat also generates quite some spray, something I relate to that the lines have quite some radius in the bow section, which also would become smoother if extended.

2. appearance

lenghtening the hull will stretch it lines and make it's appearance significant more elegant (personal view). and an eliptical bow, well that's really somthing from the past...

Posted By: scooby_simon Re: extending hulls? - 12/20/06 10:04 AM

@John:

two reasons

1. functional

the SC20 has a nosediving tendency which is reflected in the fact that the boat nowadays only exist in a 2 feet longer version (ARC22). I think I don't have to raise the benefits of more volume in the bow, specially when its increasing the waterline length... as intended. curently the boat also generates quite some spray, something I relate to that the lines have quite some radius in the bow section, which also would become smoother if extended.

Fit T foil rudders - Far cheaper and simpler !

Posted By: Dirk Re: extending hulls? - 12/20/06 10:06 AM

Erez, thanks for the link, but this guy cut away, not added! :-) hope so he added volume by opening the underside, otherwise he ended up with a real wave piercer... ;-)

Posted By: Dirk Re: extending hulls? - 12/20/06 10:11 AM

simon, surely would help nosediving, but you have to inforce the transom, change the ruddercastings (how about kick-up?) AND still have to build new rudders. AND you still have an old fashion eliptical bow...

ORMA 60 style curved daggerboards would be cool so, just guess they would need to be positioned further forward than the current ones.

Posted By: windswept Re: extending hulls? - 12/20/06 06:41 PM

You might also consider actually shaping the foam extention so that it is closer to a wave piercing design than the current shape of the bow. As to how to approach the project, you might try contacting Ben Hall at Hall spars and have him send you the information of his renovation of a Waterat A-Class cat. The project was dubbed the Flyingrat. You should be able to attempt this extention by roughing up the gelcoat/paint in the area that you are attaching the foam to, getting the shape of the foam so that it fits over the end of the existing hulls. Epoxy glass to the inside to stiffen and strengthen the foam. Use a structural filler (West System has a few good fillers for this) and then fit it on. Glass the outside of the foam, use carbon fiber toe at the connection point if you feel that the hinge point needs greater stiffening than glass will give you. I would look at approaching the actual connecting joint as a scarf joint. This would allow you to increase the surface area of the epoxy joint. Anyway, good luck with the project. You can find Ben Hall's email address on the usaca web site. I will try to attach the Flyingrat file to another posting.

Posted By: windswept Re: extending hulls? - 12/20/06 06:47 PM

FLYING RAT PROJECT

The 2002 World Championships provided a great benchmark for comparing boats, spars, sails and of course sailing technique. Once again the Aussies showed us the way. Glenn Ashby's performance was nothing less than remarkable. Glenn excelled throughout the varied conditions (5-20 kt.).

The weapon of choice for the 5 of the top 6 finishers was the Flyer. Many of the top sailors in the class have gravitated to this design due to its success in the previous three World Championships. Other competitive designs sailing were the Melvin Waterat, the Boyer Mk 5, the Marstrom and the Boyer Mk 4.

I had been tempted to go with the flow and sail a Flyer at the Worlds but I had a lot of time in my Waterat and it was setup exactly to suit my style of sailing. My speed at the worlds was quite good, especially in the 5-10 knot range and at the top end in 17-20 knot range.

After analyzing the results and on the water observations, I determined that if I could improve my existing boat just a little bit I'd be very close to Flyer performance in most conditions. The big question was how to improve this boat.

One of the most noticeable differences in the Waterat and the Flyer is the height of the bows. The lower windage bows of the Flyer are definitely a plus. The other noticeable difference between the Flyer and the Waterat was the under water shape of the bows from the main beam forward. The Flyer here is basically "U" shaped while the Waterat is "V" shaped. The Flyer shape allows for easier turns and less pitching.

I decided I liked the back half of my Waterat but wanted to change the bows to be more "Flyeresque". My first thoughts were to modify the existing bows by a series of pie cuts, tucks, adding etc. and then fairing the re-shaped bows. While talking with Andrew Gaynor (USA 133), he jokingly suggested to just cut the bows off and put on new ones kinds like "Prada" was doing on a regular basis in Auckland. I thought about it for a while and decided that this was "not a bad idea". The next step was to bounce the idea off Pete Melvin. Pete said he would take a look at the existing design to see if it made sense. Pete ran a bunch of numbers and proposed a new bow design that started 3" in front of the main beam. He did ask me "Why not do the whole boat?” The problem was I did not have time to make a whole new boat. I wanted to sail in the Tradewinds and A Cat "Olympic" Key Largo Regattas. It was already mid October and I needed the boat on the trailer ready to head South just after New Years.

The challenge was to make a set of female molds that would produce a set of parts (bows) that would exactly match the existing hulls just in front of the main beam. This is where computers, DFX files, and CNC cutters make a job like this possible. Pete sent the lines files to Henry Elliot (C Class "Cogito" builder) who fired up his CNC router and cut the female molds. To reduce time and cost Henry chose dock Styrofoam as the mold material. After the shapes were cut, Henry covered the Styrofoam with three layers of 4 oz. Fiberglass cloth. We then sprayed the molds with Duratec and wet sanded them to 400 grit. We then Freekoted and waxed the molds. Instead of gel coat we sprayed Awlgrip 545 epoxy primer in the molds and let it dry overnight. Prior to lamination we scotchbrited the 545 and wiped it clean. The laminate used (starting from the outside skin) was 4 oz. glass cloth, 6 oz. carbon cloth, ¼" Nomex honeycomb and 6 oz. carbon cloth on the inside. We chose Gougeon Proset (laminating) epoxy resin. The entire laminate and core was put in the molds in one shot and then vacuum bagged. In the molding process we created a centerline flange in each half to have a good gluing surface. Once the bow halves were molded, we glued the two halves together to make a complete bow section. The excess glue was cleaned up on the seam and then we were ready to attach the bow to the old half of the hull. We put a 4" wide rebate (about .030 thick) in the area where the new bows joined the old hull. The core in the original hull is 3/8" Nomex honeycomb. The joining method ended up very simple. We dug out the core of the old hulls to a depth of about 1 ¼" but were careful to leave the inner and outer skins in tact. Since the new bows had the rebate and a ¼" core, the bows were inserted into the 1 ¼" deep gap with lots of thickened epoxy adhesive.

We set up a rigid fixture to hold to two halves at the hulls in exact alignment (a lot going on here) while they were being bonded together.

Once the bows were glued on, we taped the seam with a 4" band of carbon around the entire joint and then faired the area.

The next step was to "beam-up" the hulls. I had decided to get rid of the previous bolt on method (OK but it did leak a bit and would require a frequent tightness check). I made the decision to glue the beams in place and over wrap the beam/ hull joint. This creates an incredibly stiff connection. The bad news was the boat would no longer be able to winter in my basement (door width only 7"). To improve water flow from the bow the over the beam we fashioned a "ramp" to fair the hull/beam joint. This ramp was foam covered with one layer of carbon cloth.

The final modification was install "rails" to the hull to make the boat max width for trapezing. Again we used shaped foam covered with one layer of carbon cloth.

The next step was sending the boat off to the paint shop. We used white Awl grip 545 Epoxy primer and wet sanded the hulls to 400 (leaving a semi gloss finish).

After paint I installed a new bright blue Kinder tramp and reinstalled all the hardware. Wow the boat looked brand new!

It was now time to head off to Key Largo to try out the "Flying Rat" for the first time. I was able to tune up with Mark Sellnau the day before the Tradewinds. Mark has a Waterat virtually identical to my boat (before the modification). In the lighter wind range our speed was very similar both upwind and down...So far so good...at least it wasn't slower. As the wind increased to the 14 knot I had a slight speed advantage... maybe due to less weather hull windage?? The other thing that was quite noticeable was the ease of turning the boat. This was most evident when making the turn at the bottom mark.

Now it was race time at the Tradewinds. Weather was nasty...cold... with a frigid 18-20 breeze kicking up a nice shop. These were great conditions to see if this modification was worth it. Good news...Three firsts... I am happy, the boat preformed well on all points of sail. Lower windage, easier turning, and less pitching all made small improvements around the course.

Posted By: Dirk thanks for feedback! - 12/21/06 03:09 AM

@windswept

thanks a lot for the detailed tips and posts!

although I do not plan such an extensive (and structural) modification than the flying rat is about, it indeed consist of some useful hints!

I thought about the flyer waverpiercing bow, but it's there already: I just should mount the hulls opposite up! on a more serious note, the SC is quite a typical V shape and while extension seems makeable, to add that much volume like nowadays designs would surely mean to cut the lower part of the existing hull open to widen it, something I really don't want to do. I would have to extend it to an amount people might call it team phillips afterwards ;-)talking about this 'wavepiercing' hype, I am pretty sure the SC 20 is much more wavepiercing (and less pitching) than my Flyer A-cat ever was... the Flyer shape has much more lift generated planning tendencies, that's where it's major advantage becomes evident.

your comment on the scarf joint is interesting! what exactly does it mean/look like?

do you think stock foam(closed cells) like used for underground building insulation (mostly grey, green or blue) would be suitable? I have seen the ship-models used for tanktesting also uses this (while not encountering any side forces so).

Posted By: Erez Re: thanks for feedback! - 12/21/06 05:44 AM

do you think stock foam(closed cells) like used for underground building insulation (mostly grey, green or blue) would be suitable? I have seen the ship-models used for tanktesting also uses this (while not encountering any side forces so).

In the next links you will fined useful information

http://www.boatdesign.net/articles/foam-core/http://www.diabgroup.comhttp://www.gurit.com/index_en.htmlhttp://www.alcanairex.com/alcan/acsites.nsf/pages_acai_en/index.htm Posted By: Keith Re: thanks for feedback! - 12/21/06 03:55 PM

I'm not sure anybody else has said this, but wouldn't it be easier to simply get a 22? It's essentially a 20 TR, built very nice with 2 more feet.... <img src="http://www.catsailor.com/forums/images/graemlins/wink.gif" alt="" />

Posted By: Dirk Re: thanks for feedback! - 12/22/06 02:09 PM

dear erez, thanks al lot for your links! specially the first one on boatdesign seems a very valuable source! I am aware that foam cores for marine sandwichconstruction differ from the building material foams used mostly for thermal insulation reasons. but having to deal with the limitations of the Chinese market and the not to strong forces to expect in that area, would this kind of foam still work?

Posted By: Dirk Re: thanks for feedback! - 12/22/06 02:12 PM

keith,

if you know someone willing to change boats and ship it here, very happy to 'upgrade' indeed...;-) for the moment I have to scope with what I have... and honestly also the bow of the ARC 22 (while more straight than the one of the SC20) is also not the most beautiful one...

Posted By: TEAMVMG Re: thanks for feedback! - 12/22/06 05:19 PM

Dirk

you will probably find that your resin will melt the cheap foam, things get messy and a bit out of shape then! test a chunk of foam first.

paul

Posted By: dacarls Re: thanks for feedback! - 12/22/06 08:21 PM

Colored polystyrene closed-cell foam will dissolve in polystyrene resin, styrene, gasoline, acetone and a million other solvents. Polyurethane foam will not.

More than this gets more involved.

PS: If you ever get to Florida, stay away from Bill Roberts who might want to punch you in the eye. (Thats a joke- he wouldn't really)

Posted By: Dirk bows - you love them or you hate them - 12/23/06 12:59 AM

paul & dacarls, thanks again for the input!

regarding the designer of the boat, I think he designed and build a wonderful boat. this boat is from 1980 and at that time it surely must have been outstanding in terms of how much detail thoughts went into the design. its one of the few beachcats you really can see that many issues were thought about deeply and answered in a very clever way, something you still lack nowadays with a lot of modern or so called high-tech designs. I am pretty sure if the designer wouldn't have developed this boat back in the late 70s and would start nowadays at least the bow section would look different. In that time it was designed, curved bows were quite standard on tornado, dart, hobie etc. and you can also not blame a producer to keep his line. look at the hobie tiger in comparison to the nacras. nacra meanwhile builded 4(?) F18 designs while hobie just stick with their initial one and still be able to pull it off in the worlds.

when th A-Flyer came up, I remember a lot of people saying how ugly it looks, that the boat is upside down, etc... I simply loved the look! So really hope nobody wants to punch me in the eyes just because my eyes don't like to see too many eliptical bows nowadays any more... ;-) I am just trying to see two less in 2007!

And Florida? Well, I really try to avoid too beautiful places in fear I don't would like to leave ... <img src="http://www.catsailor.com/forums/images/graemlins/grin.gif" alt="" />

Posted By: Jake Re: bows - you love them or you hate them - 12/23/06 03:38 AM

nacra meanwhile builded 4(?)

Actually they are only on the second hull shape with the infusion.

Posted By: BobG Re: thanks for feedback! - 12/23/06 02:49 PM

Dirk what's better the "Spitfire" or "Folke Wulf" ? <img src="http://www.catsailor.com/forums/images/graemlins/grin.gif" alt="" />

Posted By: TEAMVMG Re: bows - you love them or you hate them - 12/23/06 04:20 PM

I make it 3 F18s Jake;

Inter 18

F18

Infusion

Posted By: warbird Re: thanks for feedback! - 12/24/06 07:05 AM

Dirk, good luck with your project! Please keep us up with the play. I know some of the drive for such a project is the creative spirit.

I have a Taipan project which could eventually gain from such a move.

Posted By: davefarmer Re: extending hulls? - 12/24/06 07:20 AM

Dirk,

Not sure it would be of interest to you, but I have 2) SC20 bows (maybe 4' long) in excellent condition. Would be a relatively easy splice I think.

Dave 509 276 6355 Spokane, WA

Posted By: Jake Re: bows - you love them or you hate them - 12/24/06 05:51 PM

I make it 3 F18s Jake;

Inter 18

F18

Infusion

I thought the Inter 18 was around before F18 (it had a carbon mast) and was grandfathered in in hindsight after F18 came about. - I don't think that counts.

Posted By: TEAMVMG Re: bows - you love them or you hate them - 12/24/06 06:11 PM

Fair comment Jake, for a yank!

The inter18 was only available in europe with a ali mast and F18 was up and running earlier over here.

SO WE CAN BOTH BE RIGHT!

Happy Christmas

Paul

Posted By: sparky Re: bows - you love them or you hate them - 01/02/07 07:19 PM

I thought the Inter 18 was around before F18 (it had a carbon mast) and was grandfathered in in hindsight after F18 came about. - I don't think that counts.

Pete Melvin and Gino Morelli designed the Inter 18 specifically for the Formula 18 Class Rules and was sold with the aluminum mast in Europe. The carbon mast was an "extra cost" option sold exclusively (I think) in North America. Nacra also offered a larger mainsail for the carbon mast Inter 18 in the 2nd or 3rd year. All of the Inter 18s can be fully legal F18s if you use the aluminum rig and F18 sails.

Posted By: Dan_Delave Re: bows - you love them or you hate them - 01/03/07 02:20 AM

Les:

I think the Inter 18 used the same snuffer system that the I-20s are using. They are made of carbon fiber and not allowed in Formula 18 class racing.

Of course if someone is going to change out a mast then the snuffer should be no big deal.

Let's say that someone wants to upgrade an Inter-18 to Formula 18 and has the average one. They will be trading out a carbon mast for aluminum. Let's call that $900. They will need a new sail to fit the aluminum mast, I doubt that the same sail would work on the Carbon Mast and the Aluminum Mast competitively. That sail will run $1500. Then if you need to replace the snuffer you are in at least $300 for that. Now you are in an Inter-18 for $2700 not including what the boat is worth. Say the boat is worth $3000. You are up to $5700 for a boat that may or may not be competitive with the boats sailing today. If you are in this position you may consider getting a used formula 18 for about $8000.

If you were to buy a used Formula 18 for a good price you could sell it later and not lose too much money.

Just thinking before an upgrade may save some money and grief.

Later,

Dan

Posted By: rsubishop extending your hulls - 01/03/07 03:04 AM

Dirk,

use the blue foam you're talking about. its cheap and VERY rigid. It is every bit as rigid as the poly cores. to shape use adhesive backed 36 grit abrasive on a flat "stick" as a file. then sand with 80 grit before glassing. you will HAVE to use epoxy. everyone is right in saying that polyesters and vinylesters will melt the blue foam. I recommend Gougeon bros Pro set. stay away from the west systems. west is made for coating with light amine blush, but is not structural in anyway. in temps above 80 degs it will become soft and heat deflect. I learned this the hard way with bicycle frames. we shaped blue foam cores and wrapped carbon with west systems. I always thought it was my imagination that the bike was more flexible in hot weather until i made some flat carbon landing gear for my rc plane and watched the wheels turn outward 45 degrees in mid 80's weather. Anyway, shape away and have fun, would love to see pics of your progress

Posted By: basket.case Re: extending your hulls - 01/03/07 03:52 AM

Dirk,

use the blue foam you're talking about. its cheap and VERY rigid. It is every bit as rigid as the poly cores. to shape use adhesive backed 36 grit abrasive on a flat "stick" as a file. then sand with 80 grit before glassing. you will HAVE to use epoxy. everyone is right in saying that polyesters and vinylesters will melt the blue foam. I recommend Gougeon bros Pro set. stay away from the west systems. west is made for coating with light amine blush, but is not structural in anyway. in temps above 80 degs it will become soft and heat deflect. I learned this the hard way with bicycle frames. we shaped blue foam cores and wrapped carbon with west systems. I always thought it was my imagination that the bike was more flexible in hot weather until i made some flat carbon landing gear for my rc plane and watched the wheels turn outward 45 degrees in mid 80's weather. Anyway, shape away and have fun, would love to see pics of your progress

it is not the west that fails at 80, it is the foam. i just finished the molds and boat for an open 60 mono project. we used the west 105 to sheath the molds and it was fine. we also used some of the blue foam (sm) in some of the ovens and it turned into a big blue puddle.

oh, and the gougeons make west.

Posted By: Jake Re: extending your hulls - 01/03/07 04:09 AM

I agree with basket case. The blue foam is simply not a structural foam. It is designed specifically for cost effective insulating properties and it is substantially weaker in shear than the foams that are designed to be used in laminate cores. In a properly designed laminate, the core should largely resist shear loading. Use end grain balsa or the foams designed for composite core applications if you want to achieve reliable results. You will also find that you will get a much better bond to the foam (and a significantly better structure) with pressure applied to the laminate during cure (autoclave or vacuum).

I've had no heat issues with the West System epoxies...although almost all epoxies will get soft if you heat them to high temperatures. Also note that epoxies are affected by UV so if you are leaving them bare and exposed to the sun without a UV barrier, they will yellow and can get brittle.

If you really insist on cutting corners, you'll have better results using green rigid PVC foam from a floral shop than the blue stuff from a home improvement center.

Posted By: rsubishop Re: extending your hulls - 01/03/07 04:15 PM

correct, blue foam is not a designed structual foam as compared to say klegecell or any of the others, but its cheap and available in thickness and easily shaped and is typically lighter. we made a 3.1 lb carbon bike frame with it and got carbon bike of the year in '91 from bicycling mag. call gougoeon they will be happy to tell you west is not for structual laminates but for coating and recommend their pro-set series as they did our buisness here. we still use the west for coating thermoform tools if our customers wont swing for an aluminum tool, but for structural lams the pro-set has a fairly impressive set of physicals. Jake, how would an autoclave help you apply pressure to the surface of your laminate against your foam? the vacuum bagging works well, but room temp resins dont require an overall higher atmosphere to go through their cure cycle typically which is what the autoclave is there for. I dont see how the author here is going to keep a normal atmosphere behind his foam to allow an autoclave to work as your recommending, but again, bagging is a great suggestion to him. and i'm sorry but i disagree that the floral pvc would be better. the cells are too easily crushed. it is possible to make a ligther lam with the blue foam, its a tighter cell and holds less resin. it is not as structural, but it sounds like our author is not looking for overal structure, but simply changing shape, and the way he would be encapsulating the foam, I feel the blue would be strong enough. I definitly would not use it for a structural item where I was relying on the core as in a flatter 2-d laminate such as the skin of the hull. i used klegecell in my carbon daggers.

Posted By: rsubishop Re: extending your hulls - 01/03/07 04:32 PM

it is not the west that fails at 80, it is the foam. i just finished the molds and boat for an open 60 mono project. we used the west 105 to sheath the molds and it was fine. we also used some of the blue foam (sm) in some of the ovens and it turned into a big blue puddle.

oh, and the gougeons make west

yes gougeon makes both systems and they market the west to the home-built boaters due to the low amine blush. the pro-set is aimed more at industry, but the amine blush is so high its sticky when cured, but neither system is for tooling?? and you are very correct, blue foam and ovens dont mix <img src="http://www.catsailor.com/forums/images/graemlins/smile.gif" alt="" />

Posted By: rsubishop Re: extending your hulls - 01/03/07 05:15 PM

A blue foam will be MUCH lighter. the frame we designed for our client was origionally cut from structural urethane foam for its core. the core alone was 2.5 lbs which didnt leave much room for carbon. the blue foam core was .75 lbs. the "structural" cores are designed for sandwich laminates. you are not doing that. you are covering a shape. here's my analogy: if your final goal is a 10 lb structure. would you rather have a heavy core and not much skin, or a light core and 4 times the skin? theres more strength and stiffness in the additional carbon, if and only if you have a one piece design, or a solid core. the blue foam allows you to make a more similar construction. more laminate weight less core weight. they are talking about shear strenght etc....flat panel construction uses cores to give a "3rd" demension to the construction for rigidity. that rigidity depends upon the shear strenth to hold the sandwich together. this is where the designed cores shine. you are not constructing like that. you are making a SOLID shape and covering it. completely different. you will end up with a more "one piece" construction as our bike frame. boat hulls are made in multiple pieces and assembled to some degree, are very hollow, and are resonably flat. so the walls need the structural core to keep rigid. your "solid core" construction does not follow that ideal, so your choice of materials needs to follow your need, not generic construction theory. just my very humble opinion

Posted By: Dirk Re: extending your hulls - 01/05/07 05:38 AM

thank you rubi, jake and the other authors again for the detailed informations and and very helpful hints.

rubi, I totaly agree that the only forces I expect the extended bows have to deal with are those from the waves.

while those can be significant, I also believe that the blue foam would be stiff enough if coated well on the outside.

how thick would you suggest to make the skin if using glassfibres? would 2 layers of 160 g /m² do the job?

I will try to use the vacuum principle to get a good connection between the glass and the foam.

anyhow, will surely keep track with a camera once action starts and will report progress than. :-)

Posted By: basket.case Re: extending your hulls - 01/06/07 02:52 AM

3 plys 200 gram boat cloth. (fine woven cloth)

Posted By: rsubishop Re: extending your hulls - 01/07/07 03:56 AM

I honestly cant tell you how much material to use over the outside, but i can tell you to add an extra layer to allow finishing. you can easily sand through an entire layer while finishing. once the last layer is on, keep brushing a thin coat of epoxy at each "b" stage until the last weave is completely filled before sanding. filling the weave completely will not really add weight as most will be sanded off, but it will keep you from sanding into the glass too much. be sure to grind into your origional hull at the overlap at a very long taper to glass onto and to aid in finishing the seam.

Posted By: Dirk SC20 loose forestay tangs? - 01/08/07 09:53 AM

I noticed some horizontal possible movement in my forestay tangs. When taking of the cover plate, I can move them about half a centimeter fore and aft. In contrast, there is no noticeable movement in the direction the forestay pulls so. Talked to Aquarius Sails earlier and they recommended to completely replace the bulkhead with a new version for it. Since than I watched what was happening to my tangs carefully and noticed that after re-mounting the cover plates again with some epoxy no more movement occured. My guess is that the discovered aft and forward movement was probably caused by the boats earlier use on a beach where people probably pulled on the forestay when pulling the boat along the beach from and to the water. While not doing something like that anymore I wonder if I still can find out more about the construction principle of the tangs as I remember to have read somewhere else that old SC indeed might have encountered some issues with the forestay tangs being pulled out. Myth or fact? Any comments/experiences on this?

Posted By: Rolf_Nilsen

Re: SC20 loose forestay tangs? - 01/08/07 10:15 AM

No experience with the SCs, but have had a forestay tang pull out of an old Tornado while going upwind trapped (single trap those days) and full depower. This tang had just some millimeters of sideways flex on the beach. No vertical flex. Turned out it was installed in plywood with as good as no precautions to stop rot and the bolts from working on the wood. Since then I have found movement in any high load fitting holding the rig up to be unacceptable. If it was my boat, I would cut a hole for inspection and possibly remove the deck in the area for repairs/rebuilding if jugded neccesary. If Aquarius (and Bill Roberts) recommends replacing the bulkhead, it sounds like it might be the smart thing to do.

On another note:

Any hope for an F-16 report from China? Is it happening for the class there? Did you find a local sailmaker to build sails for you? If you have time, it would be good to hear from you again on the F-16 forum.

Posted By: Dirk Re: SC20 loose forestay tangs? - 01/08/07 11:35 AM

Ups! Thanks! That sounds scary! Anyone knows how the tang is fixed to the bulkhead on a 1980s SC20?

Rolf, will post on F16 regarding other topic.

Posted By: dstgean Re: SC20 loose forestay tangs? - 01/09/07 02:58 AM

If you are just adding a bit to the bow, it won't matter which foam you use since the glass and epoxy will be taking the loads. I built a pair of amas "surfboard style" with a stringer between stacked and glued pink insulation. Crappy foam? Yes. As long as the bond doesn't give way, it works great though. Think of all the surfboards that were made with less than stellar foams. Some current epoxy boards are made with what amounts to styrafoam. Your skin will be taking the loads if you don't modify the underlying hull other than roughing it up for bonding the foam and glass to it. That said, you don't need much and might be able to get some klegecell or Airex cheap.

Dan

Posted By: davefarmer Re: SC20 loose forestay tangs? - 01/14/07 05:08 PM

Dirk,

I have a couple of early 80's bows, cut off 6' from the bow. I'll try to dig them out of the snow, stick me head in there and see what I can see.

Dave

Posted By: Dirk Re: SC20 loose forestay tangs? - 01/17/07 11:56 AM

Dear Dave,

that would be really very helpful!

By the way, where did you get them from? I am familiar with some people keeping a damaged hull in storage after replacement with a new one, but this bow story seems to be a more special one! ;-)

Anyhow, if you can get an idea about the construction of the tangs and bulkhead, would really be great.

If any other SC20 sailor is reading this thread, let me know if anyone else noticed similar problems or is also sailing with loose tangs since years :-)

Posted By: davefarmer Re: SC20 loose forestay tangs? - 01/18/07 03:49 AM

I bought a very badly damaged 20, that had both hulls split lengthwise, supposedly on the trailer. I never did figure out how so much damage could have occurred. I just bought it for parts, mast, rigging, rudders and trl. About 6' of each bow was intact, so I just cut them off with a sabre saw. Keep reminding me, I'd already forgotten my offer. It's dark when I leave in the morning for work, and when I get home. That leaves the weekends when I'm usually off to the backcountry if conditions permit.

dave 509 276 6355

lightguyz@hotmail.com Posted By: Dirk to davefarmer - 02/21/07 03:12 PM

dave, still snow on the bows? :-)

would really appreciate if you could find out what the meaning in terms of construction principle is of

"The older SC20's had a vertical transverse bulkhead that supports the forestay tangs."

Thanks Dirk

Posted By: davefarmer Re: SC20 loose forestay tangs? - 02/22/07 05:52 AM

Dirk,

I stuck my head in there but can see anything useful. There's a big block of foam just aft of the tang (and bulkhead?) that obscures everything. Sorry!

I bought a badly damaged 20 that had numerous longitudinal cracks that the previous owner said were caused during trailering (hard to picture). Paid $400 and got a great mast, rudders and a Trailex alum trl I sold to a guy in Socal for $450. And two 6' bow sections.

I've had the plate around the tang come loose, but the tangs themselves have always seemed solid.

dave

Posted By: Dirk Re: SC20 loose forestay tangs? - 02/22/07 08:14 AM

dear dave,

thanks for your efforts anyhow!

by the way, did you ever lay your boat on the side (capsize) on the beach/land ? its an easy issue with an F18 or F20 but wondering a little by the width and weight of the SC20... have to replace the spin halyard block and I am to lazy to lower the mast... ;-)

Posted By: Dirk Re: SC20 loose forestay tangs? - 02/23/07 04:01 PM

done without problems.

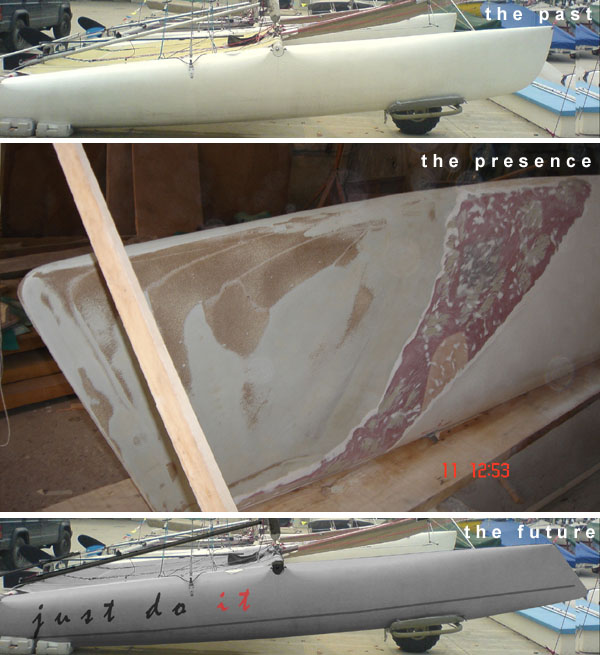

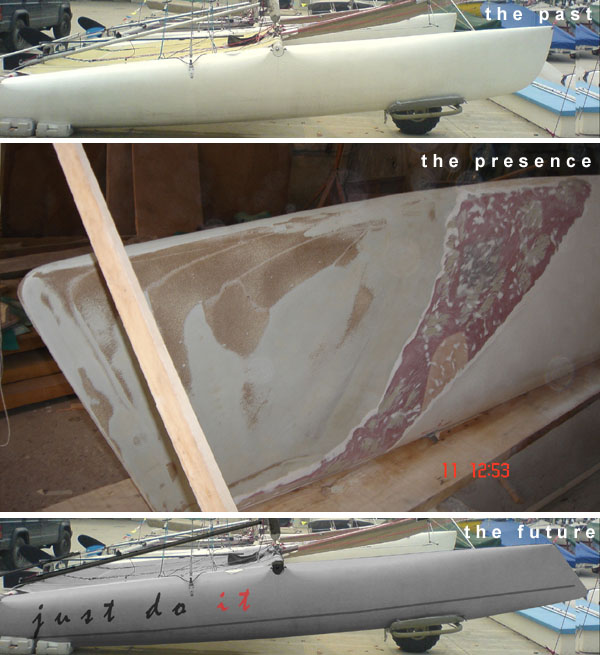

Posted By: Dirk update on progress - 04/11/07 12:53 PM

It had been a while but things are moving fast now.

New shaping took place the last three days and while I am typing the fibreglass work is moving along.

Thanks again to everyone who shared his knowledge. It did feed the motivation :-)

Photoshop is something, getting there is everything... ;-)

Posted By: Rolf_Nilsen

Re: update on progress - 04/11/07 01:08 PM

You are a brave man Dirk. Looking very much forward to hearing how this change the boats characteristica.

Posted By: Dan_Delave Re: update on progress - 04/11/07 05:19 PM

Dirk:

That is looking good. I was wondering where you were with it.

Later,

Dan

Posted By: windswept Re: update on progress - 04/13/07 12:23 AM

Dirk,

Nice going. You've come a long way to the present. good Luck.

tom

Posted By: Dirk one week later - 04/14/07 03:55 PM

Glassfibre work is also mostly done. Soon the hulls will get new gelcoat finish. This will surely add some noticeable weight (maybe up to 10kg/hull) so I wonder if it makes sense to try to sand as much as possible from the old gelcoat away to save weight? any comments?

Posted By: Dirk made in china - 04/14/07 04:00 PM

it's interesting how a nose changes a boat... the old lady (born 1980) doesn't feel that old any more :-)

Posted By: MauganN20 Re: made in china - 04/14/07 04:45 PM

Hey Dirk, that looks great!

Talk to jake about re-gelcoating. He did the blue N20 with a new shot of Gelcoat. He can probably give you a good indication of how much weight it added.

Posted By: ncik Re: made in china - 04/15/07 12:54 AM

have you considered a two-pack polyurethane paint job instead of gelcoat?

Posted By: basket.case Re: made in china - 04/15/07 01:33 AM

paint the boat. dont try to re gel it.

Posted By: Seeker Re: made in china - 04/15/07 02:08 AM

Use Duratech with the gel coat and it will turn out super..

Regards,

Bob

Posted By: Wouter Re: made in china - 04/15/07 08:06 AM

I have that on my boat and its holds up extrememly well. A few times a year my boat gets sandblasted when its in its beach side paarking, the aluminium will sometimes get discoloured by this but the paint job stayed on beautifully.

I would serious consider the two-pack polyurethane paint job very seriously for the new SC20 you have Dirk.

Wouter

Posted By: ncik Re: one week later - 04/15/07 11:42 AM

I would paint it with a two-pack polyurethane, not gelcoat.

Posted By: Jake Re: made in china - 04/15/07 12:39 PM

Agreed - paint it.

Posted By: Dirk Re: made in china - 04/15/07 01:18 PM

the point is I do not have mucht trust into the paint which is available here. I sailed a couple of painted boats and got a few of them professional repainted with the right paints, still none of them was as durable as gelcoat...

in contrast they do a perfect gelcoat job over here. the redid a couple of our daggerboards and they turn out like new. we gave them a old 470 and they redid the whole deck and bottom and it also looks like a new boat. so I know with gelcoat I know what I get. the only worry ist the weight penalty. the boatsyard estimated 12 kg each hull...

but I assume that is the quantity they need but a significant part of it will be lost when it dried? can anyone comment on this?

jake, maugan mentioned you did it before?

Posted By: catman Re: made in china - 04/15/07 01:49 PM

Nothing wrong with re-gelcoating. Looks like you have pro's doing it. As far as weight goes, Try mixing up a quart of gel and weight it before kicking and then after it's kicked. Keep track of how much is sprayed on. A bit of what's sprayed on will be sanded off during the finishing process. I'm guessing about half of it. Or, check the weight of a hull before spraying and then after it's sprayed, sanded and finished. At least you'll know and can give the rest of us an idea about how much the finish weighs. You can also sand most of the old stuff off so any weight gain would be just in the nose area.

Looks nice!

Posted By: Dirk Re: made in china - 04/15/07 02:07 PM

thanks catman,

seems you are sailing a grey boat?

I am seriously considering a light grey as the color for the boat. how do you feel with yours? would you choose this color again?

Posted By: catman Re: made in china - 04/15/07 02:37 PM

It's some wierd Canadian off-white color. They do look greyish in that pic. I had trouble matching the color to do repairs and the guy that had it before me did a bottom job with a color that did'nt match so since that pic I re-gelcoated the hulls with a color that I can duplicate. They are still very similar to that color.

Around here and the way I use my boat white or an off-white is the only way to go. If I had something like an A-cat I would go with a cool paint job or darker colors.

Posted By: basketcase Re: made in china - 04/15/07 03:28 PM

Interesting comment, care to explain more since you went the regelcoat way??

Jonathan Grant

Mesa, Az

boatless..

Posted By: Jake Re: made in china - 04/15/07 03:41 PM

If I was going to do an entire boat, I would paint it. The finish work is simply easier and you don't have to worry so much about matching. In the case of repairs or doing only part of a boat that is already gelcoated, I would gelcoat.

As far as the gelcoat goes, I gelcoated the bottom and up about 1/2 of the hull sides on a Nacra 20 (blue). The gelcoat I used covered MUCH better than the other gelcoats I have previously worked with and it took about 1/2 gallon to do both hulls. I'm guessing that a gallon may be around 12 to 15 lbs (5.4 to 6.8kg)...I used about 1/2 of that weight on the parts of the boat I sprayed. We did a white boat at about the same time and it took an entire gallon to cover a little less area.

I figure I sanded away about 1/3 of that gel (perhaps?) so we're talking about 2kg or so added to cover the bottoms and taper up the sides of both hulls.

Posted By: waterbug_wpb Re: made in china - 04/16/07 02:14 PM

Jake,

Care to PM me the details on the gelcoat you used?

Posted By: Jake Re: made in china - 04/16/07 03:06 PM

it was blue. <img src="http://www.catsailor.com/forums/images/graemlins/grin.gif" alt="" />

I guess...I need to get the info off the side of the can tonight.

Posted By: catman Re: made in china - 04/16/07 03:10 PM

Dirk, this is a better Pic of the hulls. Mine is on the right. As you can see they are white.

Posted By: Rolf_Nilsen

Re: made in china - 04/16/07 03:19 PM

What the.. hey? How are those Tornado mains working out with the non-tapered Mystere masts? They were designed for Marstrøms slender and tapered section with different spreader setups so I would think them to be a bit full?

Posted By: catman Re: made in china - 04/16/07 04:25 PM

They work out good. The T main is virtually the same size as the M5.5. To get the sail to fit the the 5.5 mast (30') we trim off about 10" off the top. On my boat the sail fits with no mods except the foot is shorter and that carries up the leech, so compared to the stock sail the T is shorter at mid girth about 14".

I have no trouble getting it flat. My mast may not be as flexible as a T's but it's flexible enough.

The sail I have there is the sail from Athens 04. It retired to Florida and is spending it's final days puttering around the Gulf and St. Joesph's sound. <img src="http://www.catsailor.com/forums/images/graemlins/cool.gif" alt="" />

Posted By: basket.case Re: made in china - 04/16/07 08:44 PM

the mystree section is the old sailcraft t section

Posted By: Dirk Re: made in china - 04/18/07 03:44 PM

jake or others:

any brilliant idea how to combine redoing new gelcoat with achieving an anti-slip area on the decks?

Posted By: waterbug_wpb Re: made in china - 04/18/07 08:51 PM

Sugar Deck

Anti-slip additive to final gelcoat shot

non-skid tape

Anything else?

Posted By: catman Re: made in china - 04/18/07 10:35 PM

I haven't had the chance to use it yet, but I think you could add some non-skid additive to Duratec and spray that where ever you wanted a slip free surface. From what I have been told Duratec is like a clearcoat. It can be added to gelcoat to improve uv-resistance and flow out when spraying,(less sanding) or it can be sprayed by it's self over a existing gel surface to restore it providing the the surface is consistant in color, (won't cover repairs,etc). I believe it has to be kicked with MEK when used by itself just like gelcoat

Hopefully some else that has used duratec might comment.

I guess another way to go might be to tape off the areas you want non-skid and just spray gelcoat. It generally is quite an orange-peel surface and that can be exaggerated with spray technique. Nice thing about that is if you don't like it you can sand it off and try something else. You can add the additve to gelcoat and spray that on or even roll it on. You most likely should experiment with these or any suggestions before applying to the boat.

My thoughts here are dealing with gelcoat only based on what you said earlier about paint.

Posted By: basket.case Re: made in china - 04/19/07 12:09 AM

i thicken gel with cabosil and roll it with a 3 inch short nap roller.

Posted By: Seeker Re: made in china - 04/19/07 01:13 PM

I E-mailed the people at Duratec with some technical questions about their product and received a detailed answer with their recommendations the same day. I love their product...I used it recently on a powerboat I am refurbishing with great results. You can see the before and after pictures...the "after" picture was before I buffed it out...it now has a great "new boat gloss" look to it. The third picture gives a hint of the gloss althought the lighting is really bad.

Regards,

Bob

![[Linked Image]](http://www.theimageplace.net/uploads/68ecfd8b92.jpg)

![[Linked Image]](http://www.theimageplace.net/uploads/fa331292a7.jpg)

![[Linked Image]](http://www.theimageplace.net/uploads/666b2a0cb2.jpg)

Posted By: Dirk black? - 04/22/07 12:58 AM

I know it's not reasonable and white would be the best,

but I am really attracted to black cats... (not the onese with 4 feets so)

The question is, if my 1980 repaired SC20 will get black gelcoat, will it survive?

We face up to 39°C here in summer with strong sun. The VX40 are autoclave and might not mind the heat, the foam of my old SC20 might think different about it.

Did anyone ever paint his old sandwich cat (I am sure it's not an issue with solid one layer glassfibre hulls) very dark and share his experience?

I had a kind of protype carbon A-cat earlier and I sailed it in carbon look for one season. The proplem occured with areas where there were some air in the foam layer and resin not fully hardened. It literally started cooking under the sun and before the Worlds in Italy at that time I found myself painting the platform white in fear of the warm south...

I don't expect those problems with the SC20, but maybe choosing black instead of a medium gray might be searching for trouble?

Attached VX40 pic.

thanks

Posted By: Wouter Re: black? - 04/22/07 01:45 AM

Never mind the foam and worry about your butt and hands.

Sailed a very dark coloured cat once and its hulls got very hot in the sun, sure makes you careful of where you place your elbow in that drifter.

Wouter

Posted By: Redtwin Re: black? - 04/22/07 12:12 PM

Wouter is right... you will burn yourself on a black cat. Actually, anything but white will get super hot. A friend of mine has a yellow H16 with very light blue decks and it gets REALLY REALLY HOT compared to my plain vanilla white hulls.

You guys in the lower latitudes really have your own special problems <img src="http://www.catsailor.com/forums/images/graemlins/grin.gif" alt="" />

Here is a photo from friday morning, shot while walking to work. Today I hope to be able to get on the water.

![[Linked Image]](http://www.catsailor.com/bb_files/105378-Bilde000.jpg)

Posted By: Dirk Re: black? - 04/22/07 01:55 PM

guys, did you ever though a woman in high heels will feel comfortable? of course, its not about being utmost practical, it's about to look good! :-) wether I can stand the heat, is not that much a question, as I intend to make the antislip deck grey anyway... and as I said, I sailed a black boat already... so that is not my concern.

My worries are potential delamination (due to the shear forces in the foam/skin...) and the lack of stiffness when the foam gets warm...

does anyone know how much warmer a black boat gets compared to a medium grey one?

I agree with Rob. A friend of mine sailed the first grey Flyer from Egner. The grey was very light (3% black in the gelcoat mix) still the boat got hot while my white one stayed just hand warm...

So is it like this, that the difference between white and any other colour is significant but wheter you take a medium dark or a real dark color doesn't matter so much anymore?

Posted By: Dirk Re: black? - 04/22/07 02:18 PM

Rolf, seems you really face different problems up there... Probably a white boat isn't a good idea there too because it's difficult to spot in the snow?? ;-)

That is no joking matter. Our hull covers are dark blue so the guys driving the shovel during winter can easily see it against the snow. Somebody left a white Opti under the snow once, not much boat left once they had cleaned up the last snowfall.

But now I am off to the club (happy happy joy joy, sailing season is finally here again).

Posted By: Dirk snowblack? - 04/22/07 03:13 PM

you send a pic with snow and talk about start of the season? ;-) while I am still wondering should I create a black beauty or not... :-)

Posted By: Rolf_Nilsen

Re: snowblack? - 04/22/07 06:32 PM

We went sailing today (jipii!!), and the snow got short shrift by the rain we had yesterday.

I dont think I would worry so much about the foam, but what about the epoxy (or polyester)? If you heat epoxy, it becomes soft. How are transparant finished carbon masts holding up? If that is no problem, I would not worry about deliminating. But practical handling, like Wouter described, could be uncomfortable.

Posted By: Seeker Re: snowblack? - 04/22/07 06:59 PM

On the diabgroup.com site Divinycell H grade (lowest performance) states the following…

“The foam can be used in sandwich structures, for outdoor exposure, with external skin temperatures up to +185 degrees F.”

You might want to be concerned about the resin as well...the heat distortion temp might not be that high for the resin.

Regards,

Bob

Posted By: catman Re: black? - 04/23/07 01:23 PM

You could always spray the non-skid with a light gray. Much less hot on the bod anyway.

I wonder what the VX's are painted with.

Posted By: phill

Re: snowblack? - 04/23/07 01:51 PM

Rolf,

I built a black boat and sailed it for 13 years.

The deck does get hot but all you have to do before you start is put your hand in the water and bring it up with some water in it and splash it over the deck. It's no big deal.

Once you're underway more often than not water is splashing up on the deck anyway.

The only real issue to consider is the breakdown temp of the resin used.

And believe it of not "resins ain't resins". They can vary a lot.

You can't compare a high temp re-preg resin like that used to make carbon masts to a normal resin used in boat constructoion.

I kept my black boat under cover until I needed the covered area to build a big boat. Then I moved out into the direct sun. Several years later the decks started to delaminated. It was the glue holding the layers of veneer in the play that gave out.

If the boat is only in the sun for rigging and sailing then black is probably going to be OK. If you plan on leaving the boat in the sun all day every day then it would be safe to choose another colour.

If you choose to have a black boat they only have two kinds of finishes. perfect and crap. I kept this in the forefront of my mind when finishing my black boat and in the end you could use it as a mirror and many did. As black shows every minor imperfection it has to be perfect.

Regards,

Phill

Posted By: Rolf_Nilsen

Re: snowblack? - 04/23/07 01:59 PM

Right, I really knew that. There are large differences between resins, and masts are probably made with pre-pregs and "cooked" in autoclaves while homebuilder resins become soft much earlier.

I like the light gray on the topsides, as it would appear to keep some of the glare down

Jake, How's that blue boat doing? It's been sailing a while. Any problems with the direct sun on it?

Posted By: Dirk Re: snowblack? - 04/23/07 11:39 PM

phil and others, thanks for sharing your experiences. delamination is the last I am looking for, I just repaired several of those spots on the old hulls... :-) I will cover the boat with a cover anyway. Here is a qoute from the manufacturer regarding temp:

"Most foams have a HTD of approximately 120 dergrees F.

Testing is usually done to a max of 160 degrees F but at that point you will see distortion of your sample. Resins usually have an HTD of about 140 degrees F."

Phil, what are the outside temperatures you encounter and did you ever measure the hull temperature of your black beauty when exposed to the sun on a hot day?

Posted By: ncik Re: snowblack? - 04/24/07 02:20 AM

With a gloss black finish, you will likely be able to see even the fairing line of your extension. Like Phil said, black finishes show up everything little bump, even stuff you didn't realise existed.

Posted By: Dirk and the answer is... - 05/12/07 04:15 PM

black!

or grey?

black!

no, grey!

or white?

black!

maybe grey?

black is beautiful, but...

grey is just grey as the sky...

white looks dirty to early,

black gets to hot...

[it was a tough decision ;-)]

boat assembling starts tommorrow.

Posted By: MauganN20 Re: and the answer is... - 05/12/07 04:20 PM

that looks really really nice

Posted By: Dirk cool submarine... hope it will float! ;-) - 05/12/07 04:38 PM

I am also pretty amazed... I can't find the joints between the old and the new... nicely done... looks much better than the Chinese AC bulb... haha ;-)

Posted By: ncik Re: cool submarine... hope it will float! ;-) - 05/13/07 12:51 AM

WHOA, I didn't realise how much rake was on that new bow!

Posted By: Wouter Re: cool submarine... hope it will float! ;-) - 05/13/07 07:43 AM

VERY nice, Dirk !

Wouter

Posted By: catman Re: cool submarine... hope it will float! ;-) - 05/13/07 10:37 AM

Nice project. Post some Pics after you get it together.

Posted By: arbo06 Re: cool submarine... hope it will float! ;-) - 05/13/07 01:35 PM

Dirk,

Beautiful job! It should be a rocket when you are completed.

Are you sailing with a tall rig? What is the beam, 8'6" or 12'?

Posted By: Dirk next step: sewing :-) - 05/13/07 03:38 PM

12", current 10m rig will be extended to 12m.

Posted By: PTP Re: next step: sewing :-) - 05/13/07 03:45 PM

That is a monster!! Looks sweet!

Posted By: arbo06 Re: next step: sewing :-) - 05/13/07 04:03 PM

Ya! Massive beam....

Posted By: Dirk massive is just another word for a certain size... - 05/24/07 12:24 AM

so it will definitely have massive sails ;-)

Posted By: Dirk problem with one hull - 05/28/07 11:38 PM

A sad surprise was waiting for me when seeing my boat last weekend: on a 50cm strip on the front one hull showed strong deformations on the surface. It did not only buckled but it seemed the foam 'shrinked' and therefore shrinked the whole upper part of the hull in this area.

First, I thought the boat yard did a bad repair job of one of the delamination parts they have been working on. But when studying it, it became clear the new damage occured in an area where no repair has been made by the boat yard, although they repaired the areas around it.

The boat has been in the sun now for 14 days and the damage must have happened within the last 7 days. The grey hulls do get pretty hot, so I am pretty sure, heat is the reason for this problem.

Where I don't have an answer to is why the foam shrinked? There was no forces put on the hull yet, as the mast is not stepped yet.

Anyone ever seen something like this or has an idea what happened? I looked carefully at the rest of the boat but this is the only bad spot.

Thanks!

Posted By: Dirk another pic after grinding away some gelcoat - 05/28/07 11:44 PM

there are these few white dots in the glassfibre layer. maybe they just happened when grinding but it also reminds me on those little holes you do when doing an easy repair job in delamination... maybe this area has been repaired via injection before using a resin not able to deal with the heat the grey hulls nowadays can reach when exposed to sun?

If however this is not a pre-repaired area, what could be the problem?

Posted By: Dirk detail pic - 05/28/07 11:50 PM

detail pic of grinded area with white spots

Posted By: ncik Re: problem with one hull - 05/29/07 01:28 AM

It looks like something hard has been rested on it and moved around a bit which dinted the foam core...

Dunno about the white dots though, it doesn't look like a resin that would've been injected behind the delaminated skin though, because you can't see the white glue behind the laminate.

Other than that, no idea...

What resin did you end up using, was it polyester or was it epoxy? From your photo's the deformation resembles very much the appearance of "shrinkage/deformation" that can occur when polyester resin is used when the percentage of catalyst has been too high when mixing. The highest percentage of catalyst mixed with polyester resin should be 2% IE 20ml of catalyst per every 1kg of resin. Never higher. The normally used percent is approx' 1.5%. The more catalyst above that 2% that is mixed, the more the shrinkage will occur as more heat is generated during the reaction and the associated uneven expansion and corresponding shrinkage with uneven core cooling will happen. The temptation of using a “hot mix” should always be avoided.

Posted By: basket.case Re: detail pic - 05/29/07 02:12 AM

What resin did you end up using, was it polyester or was it epoxy? From your photo's the deformation resembles very much the appearance of "shrinkage/deformation" that can occur when polyester resin is used when the percentage of catalyst has been too high when mixing. The highest percentage of catalyst mixed with polyester resin should be 2% IE 20ml of catalyst per every 1kg of resin. Never higher. The normally used percent is approx' 1.5%. The more catalyst above that 2% that is mixed, the more the shrinkage will occur as more heat is generated during the reaction and the associated uneven expansion and corresponding shrinkage with uneven core cooling will happen. The temptation of using a “hot mix” should always be avoided.

thats more of an in mold kinda issue.

Posted By: Jake Re: problem with one hull - 05/29/07 02:35 AM

What does the foam look like when you grind into it? Is it melted? Is the rippled surface still rigid or is it clearly delaminated and soft? Are we looking at the top or the bottom of the hull?

That looks like a PVC foam and I do have experience melting it (heat lamp too close on a warmish day)...but it took a LOT of heat (couldn't touch it with my hand). Clearly, I couldn't say "without a doubt", but I'm doubtful that the color of the boat had a direct effect on that problem...I've seen black catamarans before with standard construction and they survive. Based on limited exposure to the problem, and while I wouldn't completely rule out some sort of thermal reaction, my first guess that there might be some sort of chemical thing happening, enhanced perhaps with the heat, to distort the foam there considering all the things that have taken place to the boat recently.

Posted By: ncik Re: problem with one hull - 05/29/07 02:56 AM

Acetone soaking through the glass and into the foam? What kind of foam was it?

Does any standard structural foam react to acetone?

Posted By: warbird Re: problem with one hull - 05/29/07 05:33 AM

When the boat was repaired could something like acetone used to clean the boat run along the inside of the skin and do its damage slowly. I spilt a rust retardant on my leather car seat several months ago. I wiped it down with a damp cloth and it looked clean. Three weeks later the spill had melted right through the fabric and a month after that it was even worse.

Were the hulls sealed or tight?

Whatever, I feel for you. I would be gutted!

Posted By: catman Re: problem with one hull - 05/29/07 08:31 AM

It's not uncommon for for things like this to happen. It's one the main reasons primer or a seal coat is applied before painting. With gelcoat it isn't normally needed. However you've had some sort of reaction of old v new. You might want to seal that area after the repair. I not sure with what. Maybe epoxy primer? Otherwise you could have the same thing happen again. Good luck.

Posted By: Jake Re: problem with one hull - 05/29/07 10:49 AM

hmmm....I didn't think about the paint. What kind of paint was used?

Posted By: Dirk Re: problem with one hull - 05/29/07 02:24 PM

jake,

the boat was previous painted with a 2 component polyurethan paint, but pretty sure it was grinded away.

the new gelcoat was applied on top of the old gelcoat.

the ship yard has no explanation for what happened.

havent seen the foam yet but it was not soft, it felt pretty stable... from the outside it was more like vacuum bagging... like all the air soaked out of the foam...

I asked now if the shipyard used any chemicals to clean the hulls...

its pretty weird that it just happened so close to all the surrounding repair spots which are just fine...

Posted By: Jake Re: problem with one hull - 05/29/07 03:27 PM

Posted By: Dirk Re: problem with one hull - 05/30/07 10:56 PM

Dear all, thanks again for sharing all your thoughts and personal experiences!

I know a bit more without understanding anything :-(

Aceton was indeed used to clean the hulls (and probably when doing the repairs around the old area which got damaged now). I asked the ship yard to test what happens if they drop a bit aceton on the foam, but have no feedback yet. They say, if Aceton was the problem, than it should have reacted immideately or would have affected putting on the new gelcoat, which was not the case!

Can aceton really run into the glass and foam, remain there (normally it drys out quite quickly, right?) while the repairs are made with epoxy? so later remaining aceton (?) is trapped in the glass or foam? than new gelcoat is applied without problems because the aceton on the outside dried?

than the boat is put into the sun, and the first 7 days, there is no problem? in the second week, temperatures rises very little but somehow... something happens, the foam starts shrinking and pulls the outer layer of glass inside??? (you can really see the glass texture like you normally can see when doing vacuum bagging...)

this all is so hard to believe, as aceton dissappears fast and if the cellfoam was just damaged etc... under heat, you would assume expansion... or delamination... but how could it shrink? and why did it took two weeks to cause this damage?

This is not the only area where repairs had been made, so I am really in fear that other parts might encounter a similar problem over time?

What do you think?

Posted By: Seeker Re: problem with one hull - 05/30/07 11:28 PM

Did the guy that made the repairs for you use a heat gun or heat lamp to try to get the patch to kick faster? It kind of looks like someone was using that technique and wasn't paying attention to where it was pointing...as if they heated up the patch to the temperature they wanted and when they moved the heat source away it was still close enough to heat up the boat and was pointing in the direction of your new problem area...which just so happens to be in-between the new repairs that they did. I doubt very seriously if it was a chemical reaction with the foam…it looks to be some low level of heat distortion. Not as much as Jake experienced...but enough to make it deform.

Regards,

Bob

Posted By: Dirk Re: problem with one hull - 05/30/07 11:34 PM

hi bob,

not sure I understand you right...

the boat was fine when delivered.

it stayed fine for more than a week in the sun.

in the second week it deformed to the current state.

the only heat in that time was the sun warming up the grey hulls...

Posted By: Seeker Re: problem with one hull - 05/31/07 12:36 AM

Hi Dirk

You wrote "First, I thought the boat yard did a bad repair job of one of the delamination parts they have been working on. But when studying it, it became clear the new damage occurred in an area where no repair has been made by the boat yard, although they repaired the areas around it."

That is what I was referring too...When they did their repair the damage was done, the foam was changed once it hit its heat distortion temperature...this often causes the foam to "out gas" When in a cool environment out of the sun the laminate appears normal and the problem is undetectable...when you bring it out into the sun and the laminate heats up, gasses expand and distortion of the panel takes place. This may or may not be the cause of your problem...but it does exist...

Regards,

Bob

Posted By: ncik Re: problem with one hull - 05/31/07 12:46 AM

Acetone does sound like a long shot. Does it look like someone could've dropped a mast or rested something hard on your hulls?

Posted By: catman Re: problem with one hull - 05/31/07 04:06 AM

Dirk,

Here's what most likely happened. The old gelcoat was most likely bad which means porous. So it was painted. You decide to re-gelcoat. Ok, but the paint's chemicals have made thier way into the pourous gelcoat contaminating it. Meaning even though it appears the all the paint is sanded off some must have remained. Gelcoat will always react when applied over any paint. Wiping the boat with acetone before spraying was not a good idea in my opinion. I would never use any chemical to wipe after sanding. Soap and water and a tack rag is it. Just a lot of chemicals there. I might of missed it when reading some of the earlier posts but when I said re-gelcoating was fine I didn't know that the boat had been painted. Knowing that I would of just repainted if I were you.

Also understand these chemicals take time to cure. Its not surprising that it took a couple of weeks to show up. I only hope the chemicals have used up their energy so this does not happen again.

Posted By: Mike Hill Re: problem with one hull - 05/31/07 02:19 PM

Catman, While I agree that there are problems covering paint with gelcoat that should show up as a peeling gelcoat problem not what is happening on his hulls.

My only guess is that a heat lamp was used to set off the repaired area. The area got very hot and the foam under the skin shrunk from the heat. The outer layer wasn't affected. But now a void was under the outer layer. After the boat was in the sun for a while the unsupported outer layer of glass fell to conform to the shrunk foam. Thus causing the ripples.

That's my best guess. It doesn't help the situation but I hope that the boatyard will take responsibility and fix the issue.

Mike Hill

www.stlouiscats.com Posted By: Jake Re: problem with one hull - 05/31/07 02:54 PM

yeah, I really doubt a gelcoat reaction caused that. However, any great heat damage should have been pretty evident shortly after the heat was removed (as was in my case).

Posted By: catman Re: problem with one hull - 06/04/07 10:19 PM

Catman, While I agree that there are problems covering paint with gelcoat that should show up as a peeling gelcoat problem not what is happening on his hulls.

I'm going to disagree with you simply because I've seen the result of gelcoat sprayed over a painted fiberglass surface.

A guy I knew had a perfect 69 Camaro with a fiberglass hood. A buddy of his had one he was fixing up. Well he who had was willing to help the buddy who didn't have make a glass hood for his car. Now these guys worked in the fiberglass shop at a boatbuilding place I also worked at. It was suggested to him that he would have to strip the entire hood before he could use his hood for the plug for the mold. Well he didn't agree. He felt as long as he put enough coats of mold release wax on, the paint would be protected. <img src="http://www.catsailor.com/forums/images/graemlins/smirk.gif" alt="" /> Well he was wrong. In fact not only did it ruin the paint but extensive damage was done to gel surface and in some areas it seemed to burn down into the glass. so needless to say they both were without hoods.

Lesson learned.

Also I can't find where Dirk said heat was applied to the area that had problems. Just guessing?

In the 27 years I've been around boatbuilding and automotive finishes I've seen some really strange things happen. When you apply gelcoat over something that has been painted with the possibilty of a laminate repair anything can happen. I don't see the boatyard as culprits in bad work. They could not have known what they were getting into until they did. I would have been more suprised to hear that there was no reaction knowing what the facts are at this point.

Posted By: basket.case Re: problem with one hull - 06/05/07 02:19 AM

every mold i have ever made has beed taken off of a plug that has been painted with two part lp stuff with no problem.

Posted By: catman Re: problem with one hull - 06/05/07 09:50 PM

Well this was back in the early 80's. For all I know the hood was painted with lacquer. I watched it done and saw the results. I don't believe anyone knows what kind of paint was on the boat previously. Cause for pause I think.

Posted By: basket.case Re: problem with one hull - 06/06/07 12:51 AM

ya, you know what, we had a plug with some textured 'wall paper' on it. the paper was painted with lp, but the edges were sealed with lacquer and they [censored] themselves

Posted By: dacarls Re: problem with one hull - 06/09/07 02:46 AM

gelcoat is a pretty good solvent for paint- styrene monomer is an unsaturated molecule- the next cousin to ethylbenzene- also a great solvent.

Posted By: arbo06 Re: problem with one hull - 06/17/07 01:42 PM

Catman Mike,or anyone else,

You have got me thinking.... (smell the smoke?)

I am using 3M Acryl-Blue glazing Putty to fill fine scrathes and dings on my rudders and boards. Do you have any experience with this product? Do you know if it will react to the gel coat or styrene?

Posted By: Mike Hill Re: problem with one hull - 06/18/07 02:57 PM

I have no experience with that 3M product. I have no reason to think there would be a problem though.

I've just worked with that Formula 27 by Evercoat. Stuff works great and you can gelcoat over it and get it to match pretty easy.

Mike Hill

Posted By: Dirk Finally... - 07/30/07 12:55 PM

...she looks like a boat again!

Posted By: Dirk ...and - 07/30/07 01:21 PM

even more important: floats!

this pic was still with the old 10 m sail on the 12 m mast, but luckily in quite some breeze, so did not miss my new sails too much that day.

with so many changes to the boat, it's quite difficult to say what brings what, but regarding the hull extension I am very happy. She cuts much nicer through the waves now and splashes significant less than before. Probably the new bows also generate more lift but with the new sails and the increase mastlenght and sailarea she will be quite some beast. Hope to post better images soon. Although the new sails finally arrived, summer is here and we enjoy what all Qingdao Olympic sailor will fear... less than 6 knots of wind all day long :-(

Posted By: windswept Re: ...and - 07/30/07 07:23 PM

Nice going dirk. The boat looks great. It was a long time in coming, so go out and enjoy the light winds. In the fall you should be able to get in more full-tilt sailing.

Posted By: arbo06 Re: ...and - 07/30/07 11:41 PM

Dirk,

Is the boom original equipment?

Posted By: Dirk boom - 07/31/07 03:48 PM

no, not many details are still original.

boom is pretty different from stock.the traveller track on the boom is not a standard but works pretty fine under load.

Posted By: Dirk extruding mast? - 08/28/07 04:34 PM

hi,

some sad news from the SC 6.5 ...

she dismasted last Sunday in 15-18 knots of wind due to a fitting failure...

searching for a new mast it seems I might be able to extrude one for a much more reasonable price than shipping anything here...

as an alternative to just extruding the same profile section like the original mast, I am also thinking of a redesign. anyone out here with some experience and knowledge to share?

thanks!

Posted By: TEAMVMG Re: extruding mast? - 08/28/07 06:37 PM

If its carbon - repair it!

Posted By: Dirk Re: extruding mast? - 08/28/07 11:19 PM

Unfortunately, it is not. It is an aluminum section which already consisted of three parts and was sleeved twice. I used a carbon look sticker to cover all holes and rivets. That helped the look and the watertightness but well, guess it doesn't matter anymore...

I wonder why the mast sections we know always feature the same wall thickness around the profile? Wouldn't it make sense to have more material on the sides and less material front and aft? I guess the Taipan 4.9 section has kind of stringer reinfocements at the inner sidewalls for similar reasons...

Posted By: Wouter Re: extruding mast? - 08/29/07 06:43 AM

Indeed,

Other masts have thickened sides for the same reason.

Wouter

Posted By: Dirk Re: extruding mast? - 08/31/07 12:44 AM

hi wouter,

do you have any pics or plans of the different profile sections?

thanks

Posted By: Wouter Re: extruding mast? - 08/31/07 06:24 AM

do you have any pics or plans of the different profile sections?

yes.

I even have a "top secret" idea to give an alu mast the same behaviour (specs) as a carbon mast for only a fraction of the cost. Although producing an alu mast as a one-off is never cheap. It is the series production that really makes alu mast inexpensive.

How much are you interested in doing some experimental work ? (a retorical question off course)

Wouter

Posted By: Dirk Capricorn F18 mast profile section? - 09/13/07 12:32 AM

Hi,

would appreciate if anyone has an image or (better) drawing from the Capricon F18 or Taipan 5.7 section.

Is the wall thickness also 1.6 mm and consist of two reinforcement 'noses' like the Taipan 4.9 Superwing section?

Appreciating any feedback!

Thanks

Posted By: Wouter Re: Capricorn F18 mast profile section? - 09/13/07 09:53 AM

I have a cut-off of that section here at home. I was going to post its data and a picture of it to you soon.

Wouter

Posted By: Dirk Winter shooting :-) - 11/27/07 02:19 PM

cold & foggy

Posted By: Anonymous

Re: Winter shooting :-) - 11/27/07 05:45 PM

That is why I am moving to Fla. <img src="http://www.catsailor.com/forums/images/graemlins/cool.gif" alt="" /> <img src="http://www.catsailor.com/forums/images/graemlins/smile.gif" alt="" /> They sail all year round and LOTS of races!!!! can't wait. <img src="http://www.catsailor.com/forums/images/graemlins/wink.gif" alt="" />

Doug

Hi dirk

whaooo looking COOOOL this big SC 6.5

whatabout the all upweight now ?

Nice to see you still have the 'bastler' drive .....

should be time to introduce the A cat to china now?

what about setting up a high-tech-but-low-cost china produced acat like the blade runner moth ?

u know how to contact me....

Pieterjan.

Posted By: Dirk Re: Winter shooting :-) - 12/05/07 03:57 PM

hi PJ, great to read you here...

all upweight? better don't ask! too heavy, at5 least that's what my back tells me when lifting the boat to get the trolley under, haha...

yep, miss the A and sadly missed the worlds in Florida. must have been awesome. love what ben hall showed up with... my little tuning of the SC looks really minor compared to that, haha

yep, labour is cheap but craftmanship is bad too. you better stay besides the workers and control ever single step, otherwise you will end up with surprises... encountered some with my SC...

but if you get it right, things can still be cheap locally. export and taxes are a different story. bladerider therefore seems quite pricy but still was interested in a local build bladerider but the best they could come up with was the AUS$ and suggesting I should convert it to RMB!!! good joke. anyhow, whatever you build here, it would be for export... China isn't into sailing yet and in near future...

hope all is fine in NL! by the way, how did your ORMA style curved daggerboards turn out?

Posted By: VIRUSCAT Re: extruding mast? - 12/05/07 07:31 PM

Dirk,

in Italy we have a mast profile similar to the capri one, same dimension but 15% more weight (and resistance) we have also a joint to make it 1n two pieces

Emanuele

Mattia Italy

hi Dirk

well, I wasn't too sure of the curved boards my self, so this year I bought a new MK 2 egner platform with straight, canted boards.

The boat itself is really good , for me( 84 kgs ), defitely better then the mk1 in a breeze and solid like a rock with high mod carbon beams .

But the results were less then on my old boat with the curved boards ..... Difficult to say if the boards bring something , but it looks faster, so it feels faster, so it is faster .....

I am just thinking of building two new bananaboards fo the mk2 this winter.

ughf, then I have to put the jigsaw in the new flyer 2 for the new daggerboard cases . I need to find some courage to do that ....

Small technical point what I have to figure out is the optimal angle of the boards . My mk 1 flyer had the radius 1800 mm boards in the straightdaggerboard case.

If I replace the canted daggerboardcase from the mk2 by new one the boards are quite extreme canted in .... ( just meeting the 1500 mm rule) Nils bunkenburg's new boat has 1500 mm radius boards, under that extreme angle...

But Nils was not really as flashy as normal this season , but again , difficult to say if that has to do with the boards...

i keep you updated!

PJ

Posted By: Dirk some video - 02/27/08 02:01 PM