Catsailor.com Brainstorming help please

Posted By: hobiegary Brainstorming help please - 05/02/08 04:23 PM

I would like suggestions for what to use as a pressure relief valve.

Problem:

Sealed, watertight hulls have leaks small enough to disallow water to come in, but large enough to allow presurized water to come in.

Scenario:

Warm hull is plugged before placement into cold water. Inside air shrinks and creates negative pressure, encouraging water to rush into normally insignificantly small holes.

Solution:

During the cooling process, leave a port open so air pressure may equalize as the hulls cool down.

New Problem:

No ports on hull besides the sub-surface drain plugs.

Solution for new problem:

install a tiny pressure relief valve on each hull. Valve should be small, light, Normally Closed, and temporarily opened.

(I am picturing it to be either a small twist or a push button action.)

Seeking Ideas on what I might consider using for this valve. The valve must offer all of these functions:

1)let air to move in

2)not let water in

3)not let pressurized air out.

I'll start the brainstorming with this idea:

Drill a tiny hole (1/32" or 1/16") in each hull and cover with duct tape.

GARY

Posted By: Rolf_Nilsen

Re: Brainstorming help please - 05/02/08 04:31 PM

How about drilling a tiny hole, install a hose leading to the bottom of the hull and let the extra pressure push water out of the hull once you have positive pressure. No need to plug the hose unless you want to, but you could install a small valve there. You can find all you need at a pet shop selling fish tanks. Picked up the idea from someone describing this system installed in an A cat Steve Clark built.

Posted By: TeamChums Re: Brainstorming help please - 05/02/08 04:43 PM

Gary, don't start drilling holes in your new boat! Just hose it off before you leave the storage yard then put in the plugs. It shouldn't get that hot in Marina Del Ray to be that big of a problem.

Lee

Posted By: Seeker Re: Brainstorming help please - 05/02/08 05:04 PM

They make small plastic screw in pressure relief plugs to relieve pressure in sandwich constructed Sailboards/Windsurfers...they have been around for decades...all you would have to do is drill a hole and bed it with epoxy/cabosil...I have one in all my windsurf boards as well as in my Wave ski (surf kayak) ...anything you make out of open cell Styrofoam (surf board/paddle board/wave ski/sailboard, etc) uses one of these vents. fiberglasssupplycom has them…look in product catalog>Surfboard, sailboard and Kiteboard components…scroll down towards the bottom just after the Sailboard mast boxes…they are listed at $1.77 each…easy to install and work great. They are only 1” in diameter and water tight so you can put it just about anywhere.

Regards,

Robert

Posted By: scooby_simon Re: Brainstorming help please - 05/02/08 06:44 PM

Gary,

If you are talking about your Stealth; tale a look on the back of each hull, about 2 inches below the top rudder pintle; there is a 2mm hole there on each hull - well there is on mine!

Posted By: waynemarlow Re: Brainstorming help please - 05/02/08 08:19 PM

The early shape boats like mine and Gary's didn't have a hole drilled, simply drill a small hole high up on the transom ( perhaps behind the top pintle ), fill with glue of some kind and then drill with a smaller hole ( stops water getting into the foam ),very little water gets in.

Good fun boats the Stealth and you should have plenty of fun times <img src="http://www.catsailor.com/forums/images/graemlins/cool.gif" alt="" />.

Posted By: Luiz Re: Brainstorming help please - 05/03/08 04:07 PM

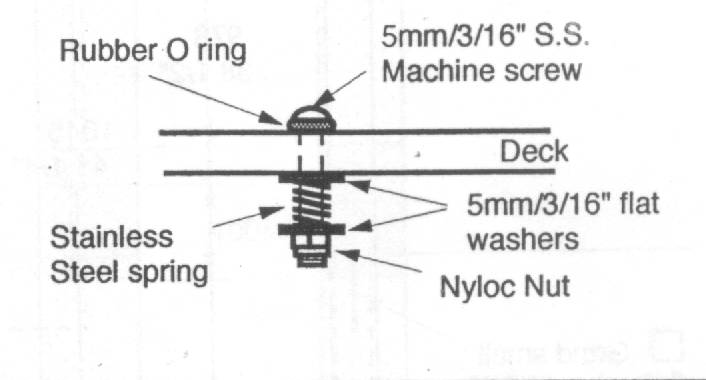

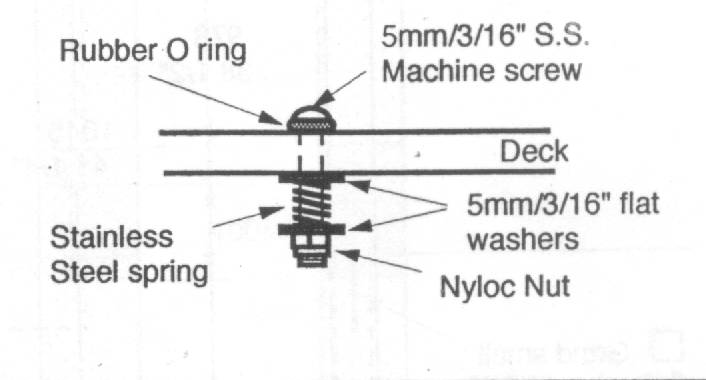

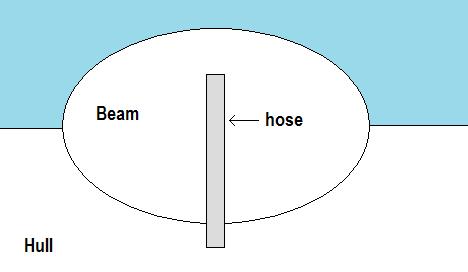

This inexpensive homemade valve can be used to relief compressed air from a hull. I guess it is easy to modify for your specific purpose.

![[Linked Image]](http://www.catsailor.com/bb_files/144283-valvulafloats.jpg)

Posted By: Tornado_ALIVE Re: Brainstorming help please - 05/04/08 03:54 AM

Personaly I leave my hatch covers off until my boat is in the water and we are about to make way.

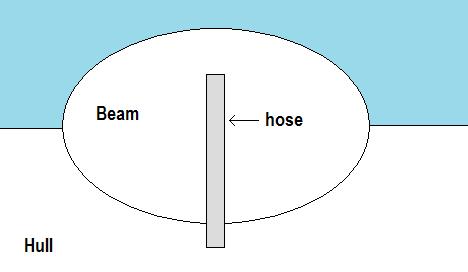

Alternatively I have had boats where a small hole was drilled where the front beam seats with a small hose sealed in the hole. Drill a small hole in the base of the front beam and run the hose up inside the beam.

![[Linked Image]](http://www.catsailor.com/bb_files/144313-Breatherhole.jpg)

Posted By: Karl_Brogger Re: Brainstorming help please - 05/04/08 04:42 AM

I have one small hole (3/32") drilled in each of my four hatch covers. I don't get anymore water than I would expect on any other boat I've owned, which is usually not much unless it is really rough, or the boat sits on it's side for a bit <img src="http://www.catsailor.com/forums/images/graemlins/crazy.gif" alt="" />

Posted By: PTP Re: Brainstorming help please - 05/04/08 03:00 PM

A hole, as small as possible- provided it doesn't get gummed up to easily - in one of the port covers would work fine and not allow much water in. The only time it would even be a potential concern is if you spent a long time with one hull in the water sideways (can't right it). I think keeping it simple here would be the best idea. But then again, now that I think of it, he said this boat doesn't have any ports. How is that possible? I would put some in then behind the front beam. But he also said the hulls are very rounded. who knows. I bet if you tested the hulls you might find that there is an unintentional leak which air can escape from anyway.

Posted By: hobiegary Re: Brainstorming help please - 05/04/08 04:12 PM

Lee,

Del Ray in in FL. Marina Del Rey, CA does indeed have enough temperature difference between water and air to induce a vacuum inside an otherwise water-tight hull. That is why I raised the request for brainstorming assistance.

But brainstorming requires well... brains. <img src="http://www.catsailor.com/forums/images/graemlins/grin.gif" alt="" />

A "special" thanks to Lee even though he didn't contribute any solution that would actually help with the problem. <img src="http://www.catsailor.com/forums/images/graemlins/tongue.gif" alt="" />

Everyone missed you at Catfight this weekend!

GARY

Posted By: hobiegary Re: Brainstorming help please - 05/04/08 04:33 PM

Thank you everyone for all the ideas. I won't criticize any of them since I asked for brainstorming; and I got it too, thanks!

My favorite one is Stepehn's suggestion of the tube that enters the inside of the beam where it will be least subject to water touching it.

Patrick, I did pressure test the hulls. There was not an above water leak where the air could enter. That was why the suction was allowing water to penetrate in the small sub-surface leaks.

By the way, I've had this problem on a few boats. The most common leak point on all of them as been the edges of the drain plug assembly. Not the plug but the base that the plug screws into. Pretty easy to repair with sand paper, alcohol or acetone, and some sealant.

Luiz, Thanks for the valve. It would require access to both sides of the hull which, I don't have. (It would also require a way to lift the small end unless the large part would be installed on the outside).

Robert, I'll certainly take a look at those valves. Might be just the thing needed but it sounds a bit larger than I hoped for.

Simon, sounds like the builder learned what I learned! Looks like they chose the driest part of the hull. This location will be easier than going inside the beam. I think I'll also use my duct tape idea to keep any additional water intrusion to an absolute minimum; only if the hole itself doesn't completely solve the problem first.

Waynemarlow, filling with epoxy and then re-drilling is definitely the way to do holes through a sandwich constructed hull.

Thanks again everyone for your ideas on how to accomplish this valve.

GARY

Posted By: Stewart Re: Brainstorming help please - 05/04/08 04:58 PM

I also keep the hatch covers off till in the water and almost underway.. I also have a small hole drilled into the hatch cover and a small tube inserted.. This then hangs down and bent back up and down again.. In a "S" shape.. allows air to flow.. but stops water... Even if water does get into the "U" it still wont get in.. just a thought..

Posted By: Luiz Re: Brainstorming help please - 05/05/08 04:14 AM

Luiz, Thanks for the valve. It would require access to both sides of the hull which, I don't have. (It would also require a way to lift the small end unless the large part would be installed on the outside).

Exactly. It would be installed upside down, close to an inspection hatch - it is good to have at least one per hull.

Two questions:

Would it make sense to install a tire valve and pressurize the hull before sailing?

Also, has anyone ever calculated if it would make sense to fill the hulls with a lower density gas in order to reduce displacement?

Posted By: walkefmb Re: Brainstorming help please - 05/05/08 03:10 PM

if you've got an inspection port put the valve of choice in that. if you don't like the setup you are then in left with two choices. replace the cap or seal it up(epoxy tape hubba bubba your choice) don't drill your hulls if you don't have too.

I have a dark hull in s.fla. and the hulls do get hot enough to cause the inspection ports to jump 4' up when realeased.

Posted By: David Parker Re: Brainstorming help please - 05/05/08 03:38 PM

I had a SuperCat 17 that had a weird pressure problem. It had no inspection ports but it did have drain plugs. After sailing and having the boat in the sun for the time it took to de-rig for trailering, I'd open the drains to drain out any water. I'd get a huge hiss of outgoing air followed by a pint or so of water. I finally decided that some small leak would let water IN during sailing but sealed itself, not letting air OUT later. It was some kind of one way leak, a diode of sorts. I never did anything about it but it did make me wonder about pressure buildup. It's always something! <img src="http://www.catsailor.com/forums/images/graemlins/grin.gif" alt="" />

Posted By: Jake Re: Brainstorming help please - 05/05/08 06:03 PM

I had a SuperCat 17 that had a weird pressure problem. It had no inspection ports but it did have drain plugs. After sailing and having the boat in the sun for the time it took to de-rig for trailering, I'd open the drains to drain out any water. I'd get a huge hiss of outgoing air followed by a pint or so of water. I finally decided that some small leak would let water IN during sailing but sealed itself, not letting air OUT later. It was some kind of one way leak, a diode of sorts. I never did anything about it but it did make me wonder about pressure buildup. It's always something! <img src="http://www.catsailor.com/forums/images/graemlins/grin.gif" alt="" />

The blue TeamSeacats N20 is the same way. when you remove one of the two hull ports from the port hull, it releases a bunch of air pressure - but the hull still gets water in it.

Posted By: mbounds Re: Brainstorming help please - 05/05/08 07:40 PM

Also, has anyone ever calculated if it would make sense to fill the hulls with a lower density gas in order to reduce displacement?

Yes, and the bottom line is that the weight savings are negligible.

Think about it this way - at 80 degrees, air weighs about 1 kg/cubic meter. The same amount of water weighs 1000 kg (fresh water).

So, say a Hobie 16, fully submerged, displaces 1 cubic meter (1000 kg or 2200 lbs of water). If you were somehow able to maintain a vaccuum inside the hulls, they would only weigh 1 kg less.

Filling the hulls with Hydrogen / Helium would weigh more and be very hard to keep inside (the small molecules have a tendency to sneak out of the tiniest holes - the reason why rubber Helium baloons go flat after a while - the helium sneaks out between the large rubber molecules).

Posted By: Tornado Re: Brainstorming help please - 05/05/08 11:33 PM

Posted By: hobiegary Re: Brainstorming help please - 05/06/08 12:23 AM

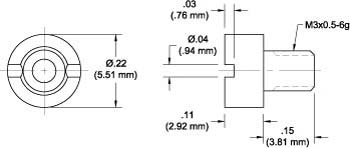

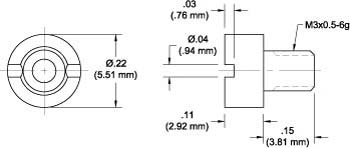

Thanks Mike; that's great! I like this one:

Mini Immersion Proof Breather TA250-1![[Linked Image]](http://www.catsailor.com/bb_files/144552-TA250-1.jpg)

![[Linked Image]](http://www.catsailor.com/bb_files/144555-TA250-1-drawing.jpg)

I could drill an oversized hole and glue it into the transom with epoxy. As long as there is a slight film of wax or oil on its threads, it will also be extractable.

Now, .... is there anybody here who can add one of these valves to their order and let me get it from you? I doubt if my local retailer will have one on their shelves.

For now, I'll use a 1/32" hole and if necessary I will cover it with tape once the hull has chilled. This will be the pilot hole for the new immersion proof gas pressure equalization valve.

GARY

Posted By: hobiegary Re: Brainstorming help please PICTURE HOLDER - 05/06/08 12:26 AM

drawing

Posted By: grob Re: Brainstorming help please PICTURE HOLDER - 05/06/08 09:53 AM

As you are brainstorming, and I have no idea if this would work, but how about covering a hole with a waterproof breathable material like Goretex?

Gareth

Posted By: Keith Re: Brainstorming help please - 05/06/08 03:15 PM

This inexpensive homemade valve can be used to relief compressed air from a hull. I guess it is easy to modify for your specific purpose.

![[Linked Image]](http://www.catsailor.com/bb_files/144283-valvulafloats.jpg)

This is what is done on the floats (amas) of Corsairs/F-boats. My F-27 has one on each float near the front beam.

Posted By: hobiegary Re: Brainstorming help please PICTURE HOLDER - 05/06/08 03:22 PM

Nice idea. I presume that the tiny "nub" on the back of my Garmin Etrex Legend is a gortex covered hole.

As you are brainstorming, and I have no idea if this would work, but how about covering a hole with a waterproof breathable material like Goretex?

Gareth

Posted By: Luiz Re: Brainstorming help please - 05/06/08 03:52 PM

This inexpensive homemade valve can be used to relief compressed air from a hull. I guess it is easy to modify for your specific purpose.

![[Linked Image]](http://www.catsailor.com/bb_files/144283-valvulafloats.jpg)

This is what is done on the floats (amas) of Corsairs/F-boats. My F-27 has one on each float near the front beam.

I have one per watertight compartment per float, six in total.

Posted By: Tornado Re: Brainstorming help please - 05/06/08 04:13 PM

I think you'd be better off with the larger/higher flow rate (~150 cc/min) unit:

![[Linked Image]](http://www.agmcontainer.com/immersion_breathers/images/TA242-1-dwg.jpg) TA242-1

TA242-1 A hull has an awful lot of volume in it and the mini valves are really designed for small electronic-type enclosures.

I found these a while back when looking for solutions for my centerboard & rudder vents. The Marstrom blades are hollow (not foam cored) and have tiny holes in them that I need to remember to tape off. It is just another thing to forget and I frequently did (still do!). Ultimately decided against the breather vavles...didn't want the protruding bits sitting where the current holes are...interfered with blade pivoting.

Posted By: CHAS Re: Brainstorming help please - 05/07/08 06:40 PM

Will be sailing at 4000 feet in cold water, then trailering back up to house at 7400+.

This keeps me busy with the plugs.

When you guys try some of these valves, please post the results.

Posted By: Timbo Re: Brainstorming help please - 05/07/08 06:47 PM

Why not just install the standard 1" drain plugs on the transoms?

Posted By: Jake Re: Brainstorming help please - 05/07/08 06:57 PM

My Boyer a-cat has a small pin hole just under the top rudder gudgeon for pressure equalization...but then again, I don't plan on crossing any oceans with it.

Posted By: hobiegary Re: Brainstorming help please - 05/07/08 08:25 PM

In case anyone is wondering which direction I've headed:

After looking at all the ideas we've generated, I've decided to go with my original plan of drilling a hole and using duct tape if I want it covered.

Since duct tape was invented for waterproofness

reference, the history of *DUCK* tape that's good enough for me. I don't really expect that I'll need to cover the hole, but may do it on long outings, only after the hulls have have cooled. (my water temperature average is somewhere in the neighborhood of 60ºF)

I've drilled and refilled a 1/8" hole and will re-drill with 1/32". Not sure if I'll get enough flow through there; tests will tell. If not, I'll go with something larger. If I have to go larger than 3/8", then I'll probably just mount a standard drain hole, high on the transom. (probably the windsurfer type that was mentioned early in the thread)

Test reports will follow, in time.

GARY

Posted By: Tornado Re: Brainstorming help please - 05/08/08 04:42 PM

Recommend against regular duct tape...it falls apart rather quickly and leave an nasty sticky mess. 3M now sells an much better outdoor clear duct tape...has reinforcing fibre, holds up for months at a time and comes off without the mess.

I use it in many places on my boat...especially for the sharp edges on the mast hounds/shackles where the spinny might contact.

Posted By: Jake Re: Brainstorming help please - 05/08/08 05:57 PM

In case anyone is wondering which direction I've headed:

After looking at all the ideas we've generated, I've decided to go with my original plan of drilling a hole and using duct tape if I want it covered.

Since duct tape was invented for waterproofness

reference, the history of *DUCK* tape that's good enough for me. I don't really expect that I'll need to cover the hole, but may do it on long outings, only after the hulls have have cooled. (my water temperature average is somewhere in the neighborhood of 60ºF)

I've drilled and refilled a 1/8" hole and will re-drill with 1/32". Not sure if I'll get enough flow through there; tests will tell. If not, I'll go with something larger. If I have to go larger than 3/8", then I'll probably just mount a standard drain hole, high on the transom. (probably the windsurfer type that was mentioned early in the thread)

Test reports will follow, in time.

GARY

That will be plenty large enough.

![[Linked Image]](http://www.catsailor.com/bb_files/144283-valvulafloats.jpg)

![[Linked Image]](http://www.catsailor.com/bb_files/144313-Breatherhole.jpg)

![[Linked Image]](http://www.agmcontainer.com/immersion_breathers/images/breathers.jpg)

![[Linked Image]](http://www.catsailor.com/bb_files/144552-TA250-1.jpg)

![[Linked Image]](http://www.catsailor.com/bb_files/144555-TA250-1-drawing.jpg)

![[Linked Image]](http://www.agmcontainer.com/immersion_breathers/images/TA242-1-dwg.jpg)