Catsailor.com N6.0NA MAST FAILURE

Posted By: CRACKX N6.0NA MAST FAILURE - 11/06/03 12:23 AM

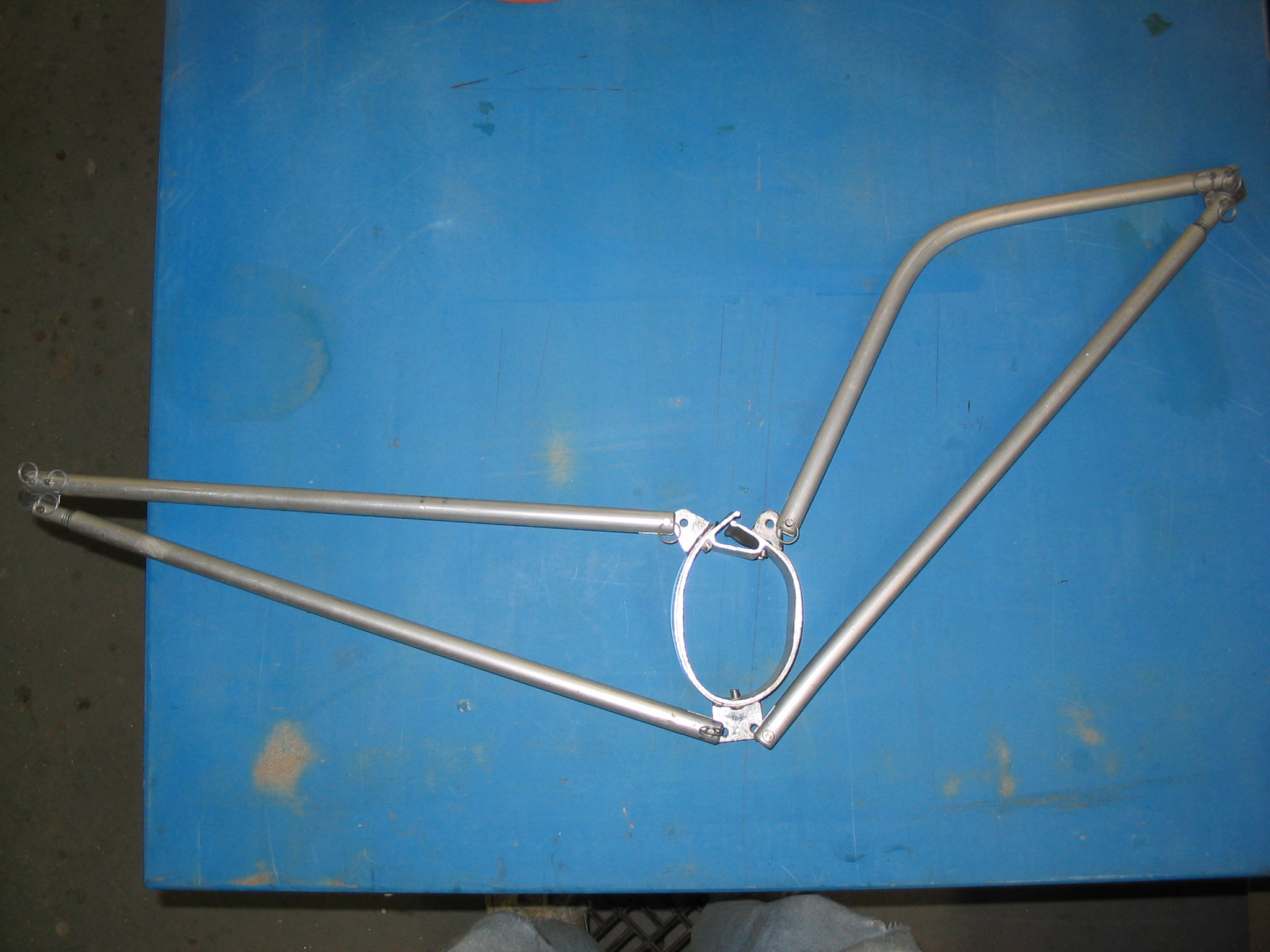

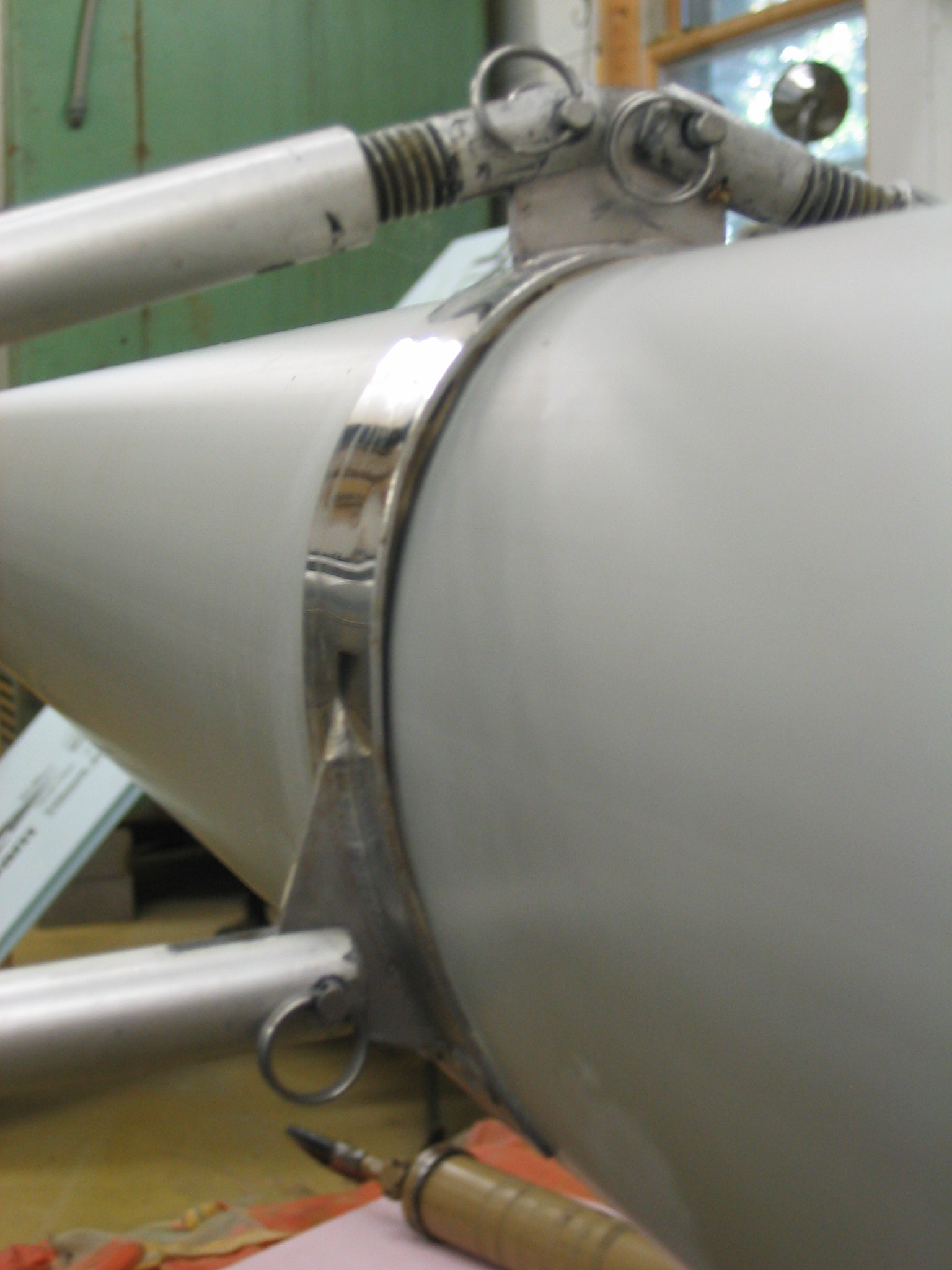

I would like to know if this has happened to any other 6.0 sailors? The particular failure that is of interest is the spreader bracket that is rivited to the mast. As can be seen in he photo attached, the tangs that are attached at the back of the mast are welded on the sailtrack side of the web. they are at an angle due to the shape of the mast, this creates a moment arm that combined with the force on the rear strut caused the sail track to collapse. this has the result of increased spreader sweep. increased sweep results in more force on the rear strut, and you get the rest.

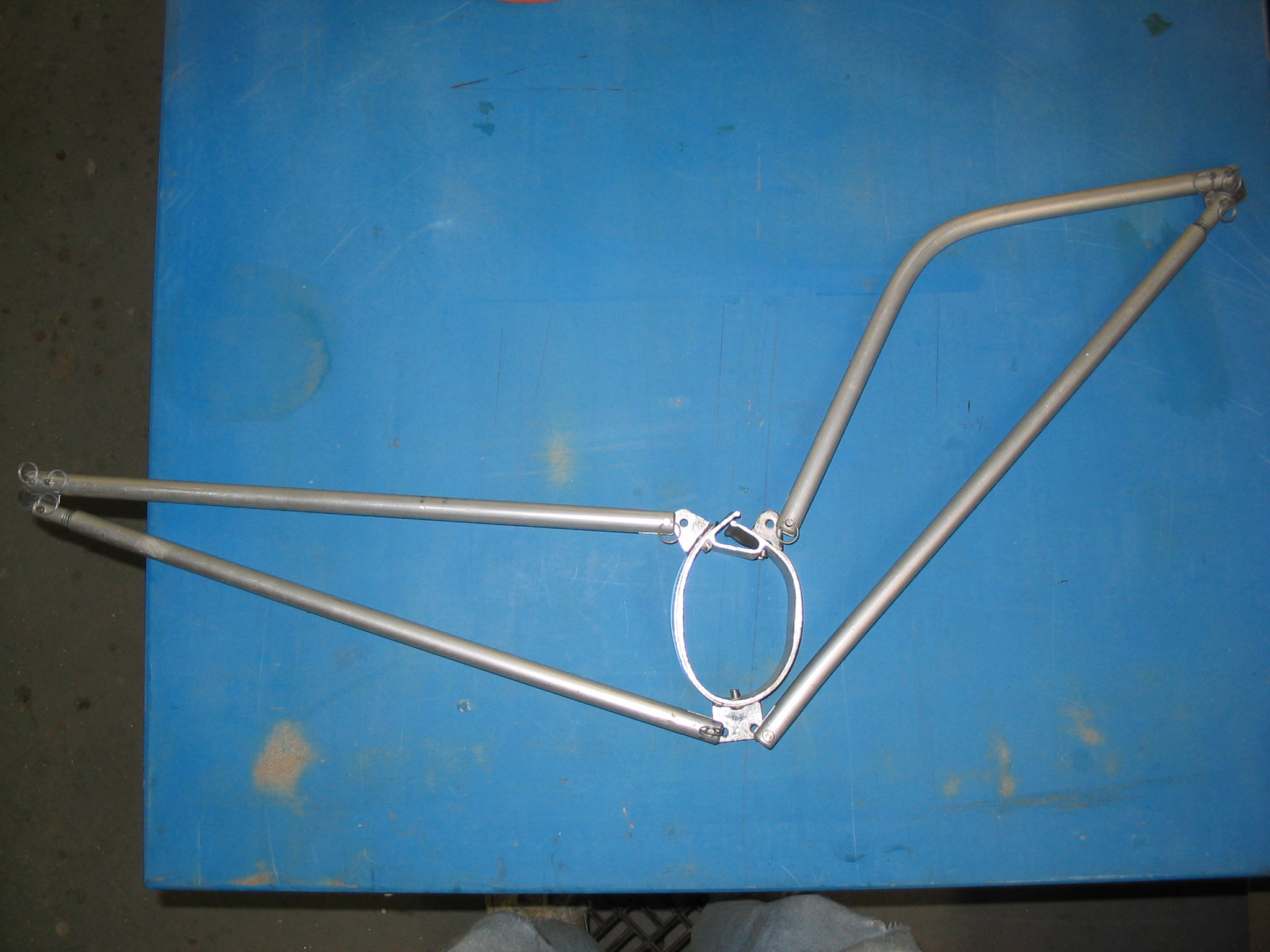

The first time this happened the failure did not go catastrophic (sp) the sail track collapsed and I had trouble getting the sail down. I bent the mast back into shape and had an improved bracket made. never had any problem after that. The improved bracket is shown in the second attachment. The tangs were moved forward about 1cm to get them on the correct side of the web and the shape was changed to spread the bending load. Jack Young was made aware of the problem and these two solutions were given at the 2001 nationals. Jack's reply was that "it never happens"

Well, recently I had to replace my mast for other reasons. I took delivery of the mast at a regatta, and so was unable to install the modified bracket from the old mast. I was disapointed that I had to even think about changing a bracket on a brand new mast, but was ready to do so as soon as I had a chance. I was busy and forgot about the bracket and two weeks later was sailing in the Sail for Hope in Newport with 400lbs on the wire, lots of wind and the mast failed. It was very disappointing to know that a $15 part could have been changed and the failure most probably would not have happened. So what I would like to know is, Does this ever happen??

Posted By: CRACKX Re: N6.0NA MAST FAILURE: Improved fitting - 11/06/03 01:38 AM

Here is a photo of the modified bracket. works great!

Posted By: Jake Re: N6.0NA MAST FAILURE - 11/07/03 11:38 PM

What kind of prebend / diamond wire tension were you running. It's hard to tell because the whole thing was probably twisted but in your first photo, it doesn't appear that the center tang (leading edge of mast) was centered on the mast.

Posted By: Todd_Sails Re: N6.0NA MAST FAILURE - 11/08/03 05:31 AM

Wow, what year mast is it?

Maybe you saw MY posts, about the 'inverting mast', on my 6.0na. It's a NA, but it was bought and sailed in #93, sail #111, I think it's #11 production model.

Anyway, my mast went, or inverted, and after taking the diamond wire tension off, it was about 18", when measuring from a straight line ene to end, to the greatest point of bend, bent forward, away form the sail track.

Some of my friends and I 'bent' it back, on some pylings at a parking area on the TX city Dike.

After I posted about this type of failure, many others posted about the same failure.

Well, I figured since it was trash anyway, wouldn't hurt to try and bend it back, which we did, then added more rake, and more diamond tension, and guess what?

Sails better, sail shape is better than ever!

Spin and all!

Never heard of this type of failure, maybe too MUCH spreader rake?

Posted By: CRACKX Re: N6.0NA MAST FAILURE - 11/11/03 06:37 PM

Jake,

The outer diamonds were set at about 35 on the loose gage, inners at about 10-15(just tight) The sweep was at about 1 1/4" if my memory serves me. I intentionally set the sweep on the low side when I set the mast up because I knew that I had to switch the bracket. I normally run about 1 3/8". unfortunately as the tangs bend in the sweep increases and all goes to hell. As I said this is not the first time this has happened to me, and I did point it out to Performance. Very disappointing. the mast was two weeks old and is not being warranteed!

Posted By: CRACKX Re: N6.0NA MAST FAILURE - 11/11/03 06:43 PM

Todd,

Brand new mast, two weeks old. 1 1/4" sweep. No bending this baby back, it is indeed trashed. Performance not going to warrantee. Spinnaker voids the warrantee. The failure was not due to spinnaker loads, but it was rigged.

Dave N6.0NA 322

Posted By: Paul_Nardone Re: N6.0NA MAST FAILURE - 11/11/03 09:57 PM

Hi -

Prindle 19 owners may want to check the spreader configuation out because briefly looking at the photo it looks like my P-19 configuration.

Paul Nardone, Jr.

Posted By: TheoA Re: N6.0NA MAST FAILURE - 11/11/03 11:37 PM

Very disappointing. the mast was two weeks old and is not being warranteed!

Thats enough to make me sick. And I'm not the one out $3000 either! I feel bad for you.

Posted By: Jake Re: N6.0NA MAST FAILURE - 11/12/03 08:55 PM

What does 35 on the loos gauge relate to in lbs? How much prebend was in the mast (displacement at the spreaders from a string running from mast tip to foot). I ask to hopefully avoid the same.

Thinking about the spreader rake, less rake (i.e. closer to straight out at 90 degrees from the mast) would apply more direct pressure to the luff groove as the loads increase. More rake would apply more of a local shear load to the mast and tang rivets and might be easier on the luff groove. I wonder if maybe having more spreader rake might have reduced the loading in that area? Just a wild thought.

Posted By: CRACKX Re: N6.0NA MAST FAILURE - 11/13/03 09:27 PM

Jake,

I do not have the conversion table with me. But rest assured that it is not an exesive amount of tension. he prebend was very slight, probably less than .5inches. The prebend is trivial when compared to the bend induced from downhaul and sheeting.

The problem is with the design of the bracket pure and simple. I suggest that you change yours to avoid any problems. I sailed with the modified bracket with no problems. it is a minor mod. you just have to find a stailess welder/fabricator. Or better yet complain to the factory. it is a desin flaw that should be changed. enough said. It is time to go ice boating!

Posted By: Jake Re: N6.0NA MAST FAILURE - 11/13/03 09:51 PM

I work for a machine manufacturer making machines mostly from stainless steel = fabrication easy!

Ice boating....Cooool! One of you guys are going to have to take me out on the hard water sometime.

Posted By: SteveBlevins Re: N6.0NA MAST FAILURE - 11/13/03 11:00 PM

Don't throw it out! Home builders can use the pieces for crossbeams. I know a guy trying to get a Inter 20 mast for his N6.0. If you don't want to try that too, maybe he will sell his old mast. Unfortunately, you live on opposite coasts.

Posted By: Jake Re: N6.0NA MAST FAILURE - 11/15/03 04:33 AM

TheoA,

The Nacra 6.0NA mast fully rigged is not $3,000...it's $895 according to Performance Cat's online 2001 pricing guide! Not too bad IMHO!

Crack,

I had some of my fellow engineers double check me and they agree that having less spreader rake actually significantly increased the compression force directly inward on the luff track of the mast. I hate to say it but this lack of rake likely caused more direct compression at the luff groove of the mast which led to the failure. The compression forces on the luff actually decrease greatly (up to a certain point) with additional sweep in the spreaders. I'll be glad to put together some drawings to further the discussion if you like.

What was the reason you had to replace the previous mast?

Posted By: Jamie Diamond Re: N6.0NA MAST FAILURE - 11/15/03 04:57 PM

I had some very scary experiences with 6.0NA mast inversion that only happened occasionally but took me quite a while to figure out. I dropped out of one Down the Bay race because this was happening and I couldn't make it stop without slowing way down.

Once I discussed it with some really good sailors and they suggested looking for a couple of things I could suddenly see what was making it happen.

Scenario:

1. I ran very little spreader rake.

2. I ran a lot of diamond tension, about 850 lbs on the outers.

3. I had a 1994 sail #141.

4. My mast would start to pump and invert in meadium to heavy air and heavy chop headed upwind. Typically I had the main sheeted very hard, yet I hadn't started to apply downhaul past the power position.

5. The mast would start to pump, invert, and make some very scary noises as I crashed into waves. When it would pop through the spreaders in mid-inversion cycle the compression loads would have momentarily been much higher and could have contributed to the type of failure you describe.

Understanding and solving the problem.

It turned out that there were a couple of other factors involved.

1. That series sail forced you (me) to run the traveler car fairly far back even when sailing upwind in a decent breeze or the bottom of the sail would invert

2. It liked a really tight mainsheet.

3. What was happening was when the boat would slow down crashing into a wave, the momentum of the sail and rig itself would keep the rig going. The mast would rotate very briefly past 90 degrees (although it was very hard to notice if you weren't queued up to look for it). Once the mast goes past 90 degrees, with the main sheeted hard, you are actually pulling forward (from the mast's perspective) on the top of the mast with the highly loaded mainsheet. The top of the mast pulling forward would act as a lever with the shrouds and forstays attaching at the fulcrum, forcing the middle of the mast backwards, inverting the mast through the diamonds.

As the mast recoiled from the "bounce" induced by crashing the chop, it would swing back to a more appropriate orientation, all systems would return to pulling the "right" way on things and it would bounce back through the spreaders into it's normal pre-bend shape with a loud metallic "boing".

A complete cycle of normal to inverted back to normal would take less than a second and would normally only happen every 3 to 10 seconds depending on the sea state. Backing of the throttle would fix the problem but didn't help me understand the problem.

The answer is 2 fold:

1. Apply backside mast rotation control at the front beam to prevent the mast from over-rotating in these conditions.

2. Add a little more downhaul to give the mast more support down the back preventing inversion.

Posted By: jdaf31r Re: N6.0NA MAST FAILURE - 11/15/03 05:25 PM

While I am not a 6.0 owner, the fact that they will not warranty a new mast because of a Spin is a serious situation that all owners, especially those with Spinakers should be fumeing about! Spinakers are in now and I imagine very few 6.0's don't use them. To not warranty a mast because it was rigged is a copout. You Dealer should also be pushing them hard to settle. Performance Cat surely doesn't need the bad press.

I sure won't buy a NACRA if they won't warranty the mast because of the spinaker being rigged. On the other hand I was out the day that CrackX mast broke, and it was some serious conditions. Enough that I was concerned on the our F31R. How much is a new Mast anyhow? Will your insurance cover it?

Posted By: Jake Re: N6.0NA MAST FAILURE - 11/15/03 08:36 PM

jdaf31r,

you are saying two different and conflicting things: A) performance should warantee the mast even though it was never designed to have a spinnaker (whether or not most of us have them) and B) the conditions led to the failure of the mast. Certainly you wouldn't hold Performance responsible for the failure considering the conditions that day - right? Who can rule out operator error? We assume a good deal of personal responsibility with how we tune and rig out boats. We also assume a lot of responsibility deciding to sail our boats in heavy weather.

At what modification stage should a manufacturer be responsible for failure? If you attach a nitrous bottle to your car engine and it dies (whether or not the nitrous was on at the time), should the manufacturer warrantee it? There has to be a line somewhere.

For the record, I have no affiliation with Performance other than owning one of their boats. However, I work for a machine manufacturer as a Customer Service Manager and deal graciously with warrantees all the time.

Posted By: TheoA Re: N6.0NA MAST FAILURE - 11/15/03 11:23 PM

I think they SHOULD warrantee the mast. It's just like a similar situation. A buddy of mine is fighting with Ford as his new cobra motor with 4300 some miles on it grenaded. Ford says that he "drove it hard".... umm, or what the heck is it for then? Are you supposed to own an SVT (special vehicle team) car and drive it like someone in a crown vic?

Likewise, are you supposed to own a Racing cat and sail it like it was a sunfish? You buy something that is 2 years old and it fails...ok, perhaps it was worn out or went through to many stress cycles....you buy something that is 2 weeks old and it fails.... start asking questions....

The more I look into class rules, and stuff like dealers not taking care of customers, the more I just want to piece a taipan together and not even think about the non exsistant but make you feel warm and fuzzy warrantee

end of rant

Posted By: Jake Re: N6.0NA MAST FAILURE - 11/16/03 04:19 PM

First, I agree - it sucks that the two week old mast failed and if a similar situation was presented to me at work, I would certainly pony up a discount on a replacement. However, a warranty covers defective parts or designs. They do not cover using an item for other than what it was intended or for any failures relative to the user modifying that design or using it outside of the specifications.

In your buddy's Mustang Cobra incident (that sucks too!) he would have to find a way to prove that something in the engine was defective since Ford has already determined that it was something outside of their control. From Ford's perspective, perhaps they suspect that he constantly ran the engine 2000 rpm over red line - they do have data logs in the ECM to record such things. If that were the case do you still expect them to warranty the engine? We know nothing about that situation but I'm trying to show that as owners we have a certain responsibility to use our equipment as it were intended. It's so typically American to not want that responsibility after something breaks. I do agree with you that the Cobra is a car that should be driven hard – but it can be driven TOO hard. It certainly would be nice if Ford were a bit more detailed in their explanation (maybe we only got half of the story too).

Even ignoring that a spinnaker was rigged, I think it's pretty clear that the mast in question was not defective - the question on the table is whether or not the design of the spreader bracket is adequate. There are a LOT of Nacra 6.0s out there and I'm sure Performance would have enough data to determine if it's a design problem. While I don't have any raw data supporting it, I've never heard of this kind of failure unless it was associated with having less than the specified amount of spreader rake - which this case clearly had. Again, I think a discount on a replacement would be the right thing to do simply because the whole situation sucks...especially for CrackX. But I don't think anyone can show that the Performance Catamaran supplied parts were defective or the designs faulty.

Posted By: Todd_Sails Re: N6.0NA MAST FAILURE - 11/16/03 06:11 PM

Jamie Wrote:

The answer is 2 fold:

1. Apply backside mast rotation control at the front beam to prevent the mast from over-rotating in these conditions.

2. Add a little more downhaul to give the mast more support down the back preventing inversion.

Hi Jamie, we've met before, when I was over Forida's way for some regatta's so time ago.

I never analyzed the forces in my masts inversion, always chocked it up to alot of double trap, in conditions like you state, and alot of chute flying, metal fatigue, (my sail used alot was #111), etc.

Interesting your statement about the backside, or leeward rotation on to prevent over max rotations. The double trap scenario also acts as a rotary force, further overrotating the mast. As stated, I increased spreader rake, and wire tensions, after manually bending the bast back from inversion-(waht a chore that was!), and even with the chute, etc, sails great again.

I agree totally with your analysis, and measures to prevent it's occurrence. I now always use some degree of downhaul, even when it's light, and always keep the main sheeting tight with the chute up, using traveler if needed. I'll definitely be trying the leeward side rotation prevention as well.

Todd Bouton

N6.0na, +

#111

Posted By: Rick_Bliss Re: N6.0NA MAST FAILURE - 11/18/03 07:31 PM

I thought it was necessary to clarify a few points.

The Nacra 6.0 was 'flying' the spinnaker when it flipped, not just rigged for one. The factory offered a new mast at a greatly reduced price (at the urging of the dealer - me) even though the mast was being used with a spinnaker. Dave commented to others on site that he was not using any downhaul while flying the spinnaker which is asking for problems. Did he let the mainsheet go to save them from going over which is a common mistake when someone has limited spinnaker experience, who knows? That often will cause a mast to snap. If he was using a Model 'A' Loos Gauge then 35 is only about 365 lbs and 15 is only about 150 lbs. which is way too little tension. His previous mast didn't fail while in use it was rolled into power lines and got zapped.

I agree with Jake's assessment about the spreader rake. I caused my mast track to squeeze slightly at the spreaders in the same race. Before the race I moved my spreader rake forward to 1 1/4" (same as Dave's) which I have never done before. I've always had it at factory specs. 1 3'4" and never had a problem. It was a windy, rough and wild race. I downhauled the daylights out of the sail like never before and the combination of that and too little spreader rake caused the mast to arc like a banana. I noticed the excessive downhaul too late. My fault, no one else's.

Te 6.0 mast hula was pretty much resolved several years ago. I haven't had it happen more than once or twice in recent years and only in extreme conditions. It used to happen all the time. Wide lower battens, move the jib cars outboard and most critical, don't bring the clew traveler car too far forward. As the wind would pick up I would usually move the traveler car way forward. I eventually realized the different angle of pull on the sail from the mainsheet system was inducing the hula. I found this out from experimenting in light conditions a few times with the car all the way forward and sheeting in hard.

Posted By: CRACKX Re: N6.0NA MAST FAILURE - 11/18/03 08:47 PM

Jake,

I disagree that less sweep increases the force on the rear spreader bar. To attain the same prebend in an unloaded mast would require tighter wires increasing the force on the spreader assembly. I set the mast up with the same tension. Once the mast is in use it does not matter anyway. the pretensioning of the wires is just to prevent the inverting that happens before you get sheeted and downhauled,and to avoid any bending to leeward, closing the slot. I did not cause the failure the design of the fitting is the cause. Please look at the picture again. Picture the forces and the moment arm with relation to the web of the extrusion. Why not just improve the bracket? I do not know why Perfomance would not want to make a slight change that would make such a big difference in reliability.

Ice boating usually is happening somwhere any weekend from december to march. The really good ice is usually first of december in these parts. would you fly or drive. You are welcome to join us.

Think Ice, Dave

Posted By: CRACKX Re: N6.0NA MAST FAILURE - 11/18/03 09:16 PM

Jamie,

My mast was not pumping and was set up the same as I have been for the entire season with one exception, 1/8" less sweep. same tension on the outer wires. so, as my mast was not pumping. that was not the problem. thanks for the description. I did ave that problem once when I first got the 6.0. Cheers, Dave

Posted By: CRACKX Re: N6.0NA MAST FAILURE - 11/18/03 09:49 PM

Yes it was some serious weather out there that day. Too bad the day was ruined because a $10 bracket was carelessly designed. It is definitely the weak link. By the time it is shipped and all it is over a grand for a new mast. I am not going to buy a new one because they will not warranty it. The one that broke was two weeks old and should be warranteed. you get the picture. At this time I will do my best to avoid doing business with Performance.

Posted By: CRACKX Re: N6.0NA MAST FAILURE - 11/18/03 10:19 PM

The design is OK, but it just needs to be modified a little. The bracket as was installed on my mast was defective. It may be that other brackets are not the same with the tangs behind the web. Please look at the picture attached to the original post and the modified one attached to the first reply. That proves that the design is inadequate or that there is a quality control problem. especially since I pointed out the flaw at the 2001 nationals. If you can improve a part markedly with a simple design change and no added cost of the unit. Why not???

I don't want to get into the discussion about what should be warranteed or not. I think when you really look at the numbers of both masts and bow foils on the Nacra 6.0 NA that fail, there are fairly large numbers. If you are going to sail and race the boat hard, the stock equipment will fail eventually. I have broken 2 foils and have had a hand in 4 wrecked masts in a 5-year span. I have had problems with the sail track getting pinched off twice. Both of these were due to the mast hitting the water or beach hard. One was a really bad pitchpole, the other was the boat flipping on the beach in a bad microburst. 2 Nacra 6.0s had masts ruined flipping on their sides in the same incident.

The interesting thing is that my original 1994 Nacra 6.0 mast has a spreader bracket that is ~ 1/4 inch shorter then the one on my newer mast. This shifts the loads to the web on the mast, not the sail track. This mast has been through hell and the sail track has not shown any sign of being pinched off. Somewhere along the line I would guess the tolerances slipped and were ignored.

On at least 5 occasions, I have lobbied Jack Young for improvements to the 6.0 that would in my estimation have made the boats more reliable while incurring very minimal expense on the factory’s part. None of these would result in speed increases or change the boat. Performance seems generally unwilling to adopt them. They have always adopted the Mantra “That Never happens” It is unfortunate because they have a generally awesome product, but still have quality issues and common failure modes that are solvable.

Eric Anderson

Posted By: CRACKX Re: N6.0NA MAST FAILURE - 11/18/03 11:03 PM

Rick,

The low priced mast came with no warranty. I was using downhaul. What was said was that I was not using a 16:1 downhaul. and I did not release the main. I repeat, why not improve the design if it can be improved? I appreciate your negotiating a discounted replacement mast with performance, but I feel strongly that the design of the bracket was the cause of the failure. Why not fix it? I think Garret and Craig had their rake set to factory specs.

Posted By: Mark Meis Re: N6.0NA MAST FAILURE - 11/18/03 11:35 PM

The factory has heard probably all the stories and in most of these cases the sailor did not respect the limits of their equipment.

I am surprised you were tuning the spreader rake for 1/8" when it was blowing like dogs. Potentially the diamonds were not set as tight as you believe. Were the wires up against the spreaders correctly, tied in with siezing wire with multiple wraps and taped. You might have thought the wires were in the slot correctly and they were not. Never no after the failure. Mast do strange things (fail) in big air when controlled incorrectly.

As I recall on my 6.0 when I finally got the mast tuned correctly the boat could handle more than the captain.

Looks like you have an insurance claim or if you paid for the mast with a credit card that gives extra protection you might recovery your bucks. Credit card claims typically need to be paid within 30 days of the failure.

Former owner of N6.0 #251 (I miss that boat)

Posted By: Jake Re: N6.0NA MAST FAILURE - 11/19/03 04:50 AM

{queue patriotic music} OK...I'm going to finish these promised spreader load drawings in the next couple of days and then I'm going to get out of this topic...promise. I'm really surprised at all of this. The Nacra boats have a deserved reputation for being bulletproof...I know mine is. How many boats with a 32' mast can withstand being turtled in 30' of water with 5 foot swells? Mine has - TWICE (yes, it's embarassing but it was an excusably violent day for a race). Hell, I cut a pretty good groove in the sandy bottom of Blackwater Sound, first with the bow and then with the mast, during a pitchpole last January. Boat Broken? nope - but I was! We righted it and sailed back to the bar. And for heaven's sake!, the previous owner of this boat once stopped 3/4 the way through RTI because he spotted a Waffle House over the trees. When he came back from his 'smacked, stacked, and covered', the wind had blown the boat over with a rudder proping up the stern - they sailed it back! These are damn fine boats. Mine has been through a lot of abuse and it's still rock solid and I'll continue to sail it for a long time. You guys disappoint me.

{end music}

{end music} I have broken 2 foils and have had a hand in 4 wrecked masts in a 5-year span. I have had problems with the sail track getting pinched off twice. Both of these were due to the mast hitting the water or beach hard. One was a really bad pitchpole, the other was the boat flipping on the beach in a bad microburst. 2 Nacra 6.0s had masts ruined flipping on their sides in the same incident...“That Never happens” It is unfortunate because they have a generally awesome product, but still have quality issues and common failure modes that are solvable.

In the same post it's stated how many masts have been seen break as a result of capsizing in the surf and on the hard...and then how it's a shame they don't make the boats better. What boats don't break masts when they capsize and hit ground in the surf or in microbursts? Maybe I should leave this alone.

{queue patriotic music again} How many Hobies have you seen pull a halyard hook out of the comp tip, How many Mysteres have pushed a chain plate rivet out the side, how many RC boats haven't had the masts sealed, how many Prindles or Tigers have had the trampoline track come loose? Every boat, every manufacturer has failures...it's statistically impossible to not have them. The question I have for you is on which boat do you feel most secure sailing across open ocean? ... I like the odds on mine.

{end music} Posted By: TheoA Re: N6.0NA MAST FAILURE - 11/19/03 06:19 AM

If you can improve a part markedly with a simple design change and no added cost of the unit. Why not???

Because if you do, you are almost openly admitting that the part isn't up to snuff, and exposing yourself for all sorts of liability issues. Sad but true

Posted By: Eric Anderson Re: N6.0NA MAST FAILURE - 11/19/03 05:54 PM

Jake I am not saying that the boats are badly built. I am not saying that the masts can ever be made unbreakable. What I am saying is that any manufacturer should be willing to make incremental improvements in their products to improve their reliability.

The fact of the matter is that a large fraction of 6.0 masts show kinking or pinching in at the sail tracks. Many of these masts were set to factory settings. Older masts had fewer problems with this because the bracket was slightly shorter. What changed? Why is the bracket now longer? The answer is most likely quality control.

I would note that between Frank Dimeo, Garret Norton, Dave Fortier, and Myself we have probably killed 16-20 masts. I would guess at least 1/2 of them should have broken given the circumstances. Several of the masts should not have broken. I do not object to buying a new mast if I roll the boat in the surf. I do object to breaking one sailing upwind double trapeezing when it was set to factory specs on a 4 month old boat.

I assume gear will fail. My sailing program takes into account periodic gear failure. I believe every single piece of the boat will break eventually when sailed hard. This is ok and I don’t have a problem with that. What I object to are things that fail regularly and are preventable through minor modification.

Examples of this are factory shrouds not being reliable, bow foil breakage, spreader and bracket design issues, jib track rivets pulling out, trampoline stitching failing (poor thread choice), drilling the ruder pivot hole in the correct spot, traveler car failure and very bad quality control on sails.

Even when numerous sailors complain about specific problems while offering better solutions that should cost very little money, Performance refuses. That is the galling part. I love the boat, the local dealer is very very good, but I do not like dealing with the company

Posted By: Todd_Sails Re: N6.0NA MAST FAILURE - 11/20/03 12:20 AM

Eric wrote:

drilling the ruder pivot hole in the correct spot, traveler car failure and very bad quality control on sails.

I always wondered, HOW, you could let who knows how many boats leave the factory, that, when you rigged them, the rudders were parrallel, on a plane different than the plane of the daggerboards? Both rudders canted to the starboard I believe it was. the gudgeons they sent to fix it, got it close, but it's still not quite in the same plane. But this was, amoung others, one of my previous posts on the now, old forum.

6.0

#111

(OLD one)

Posted By: CRACKX Re: N6.0NA MAST FAILURE - 11/20/03 04:16 PM

Even when numerous sailors complain about specific problems while offering better solutions that should cost very little money, Performance refuses. That is the galling part. I love the boat, the local dealer is very very good, but I do not like dealing with the company

That about sums it up. Galling. and in addition to the positives that Eric listed we have a local fleet of 6.0 sailors that any one would be proud to be part of and excited to race against. I will probably get over being pissed off at the factory by springtime but who knows. I like the boat, I love our local fleet and the enthusiasm and great competition we have, but maybe I will spend the summer building new go fast ice boat gear.

Posted By: Barry Re: N6.0NA MAST FAILURE - 11/20/03 05:10 PM

Dave

Or just buy a boat the comes with a spinnaker from the factory

Hope to see you on the ice this winter. I want to get on the Crack X ice boat with a GPS to see how fact we can go! I'll even scoot out on the windward plank for some extra righting moment. I had a blast when when I sailed Eric's boat. I have an extra Hobie 14 I am fixing up to sell and may have to put the funds into an ice boat.