Catsailor.com A cats and carbon

Posted By: fin. A cats and carbon - 02/15/06 02:22 PM

I hope to get an A cat soon and would like to know about maintenance.

How difficult is cosmetic care, as compared to fiberglass?

Any tips on carbon repair as compared to fiberglass?

Any dos' and don'ts' specific to carbon?

As I know absolutely nothing, ANY information will be appreciated.

Posted By: bvining Re: A cats and carbon - 02/15/06 03:47 PM

Pete,

Carbon really isnt the issue. Most of the carbon will be under some other finish or gel coat or paint.

I'm assuming you are getting a production built boat. If so, its most likely going to have gel coated hulls. Maintenance is the same as any other cat, if its gel coated.

You probably want to keep the bird [censored] off the boat and keep it covered. Or sail it every day. Covers help protect the lines, the tramp, the blocks, etc from UV. Gel coat will oxidize, but thats easily fixed and takes years, just like any other cat. Keep the sun off the boat and it will oxidize less. Keep the hulls clean and a coat of fiberglass wax/cleaner once and a while is a good idea.

Depending on the type of mast you get, you can specify the coating. I would recommend you get a mast that has a UV protective finish on it, most mast builders will be happy to sell you a clear coated mast. If not its easy to do yourself with System Three water based poly. If you dont clear coat it and leave it out in the sun for a long time, the epoxy in the mast will begin to break down and the mast will weaken. Plus it looks nicer, carbon looks nicer when clear coated. Left uncoated, carbon tends to turn greyish. I got a Hall and asked to have it painted, it looks great and will be protected from UV.

If you have clear coated carbon epoxy daggers or rudders, you dont want to leave these lying around in the sun. Bimare makes their daggers clear carbon, which looks nice, but will get hot left around in the sun. Epoxy will soften when it gets hot, and depending on the chemistry of the epoxy and how it was cured, it can soften in the hot summer sun, especially if its beating down on a black surface (carbon)

Carbon repair is the same as fiberglass, its basically the same, the cloth you are using is different, but its more about the glue you are using to bind everything together. So, you need to know if your boat is polyester resin, or epoxy resin and how these work together. For example, you can put epoxy over polyester, but not the other way around.

Carbon will get in your skin and itch like fiberglass when you sand it, so wear long sleeves and wear a dust mast, all common sense stuff. Dont get epoxy on your skin, it can cause you to be sensitized to it and then you absolutely cannot be around it for the rest of your life.

Read West's epoxy manual. It has all the info you need on epoxy.

Other than that, you need to be careful with your boat, you cant run it up on the beach, and you have to tie it down when you leave it for the evening or it will fly away if its windy.

If its going to blow big, you will want to take your mast down.

And dont make fun of plywood guys like Wouter, they get very agitated and make really long posts.

Bill

Posted By: fin. Re: A cats and carbon - 02/15/06 04:06 PM

Bill,

Thanks a bunch! I may have to drive all the up there just to buy you a beer! And besides, you have water I've never sailed!

btw- I'd never bad mouth plywood, I'm keepin' the Tiki.

Posted By: bvining Re: A cats and carbon - 02/15/06 04:08 PM

Pete,

When considering a A cat, the thing that might be a consideration is what is the core material is in the hulls.

I would want to know what fabric (carbon, kevlar or glass), what glue (epoxy, poly) and what is the core material.

As far as core material.

You can get nomex, foam, end grain balsa cores. The carbon is the skin on the outside and inside is made stronger by being held paralell by the core. Think about an I beam truss, the web (middle part) is like the core, and the caps are like the carbon skin. the whole is stronger than the parts. The American cup teams are now using honeycombed aluminum over carbon skins. The core holds the skin in suspension and it makes it stronger as a whole system.

The A2 was balsa, and I believe they have switched to nomex. (someone correct me please if I'm wrong here)

Vectorworks marine is using corecell foam as a core.

http://www.spsystems.com/solutions/...cell_A_Foam.pdf#search='corecell%20foam'All of these core materials have advantages and disadvantages. Nomex is the lightest of the cores, is hard to get, and it is widely used in the construction of airplanes. It lays in the molds very easily, especially the OX (overexpanded) stuff, so its a very easy choice for the homebuilder. But its a open honeycomb, so any pinholes in the skin will absorb at least a little water. Nomex is kevlar paper honeycomb, so I'm not sure if the water will pass between the cells in the honeycomb. In order to get a good bond to the nomex, you need to be very careful when you are laying up the skins.

Balsa endgrain is wood, so it will absorb water if the skin has any pin holes. But balsa is the least expensive core material and some research shows that wood holds up better to long term cyclical loading.

I went with foam, and you have different types of foam on the market, Corecell, Divinycell, Kegecell and Airex all have different properties.

The Vectorworks XJ uses Corecell, which is very stiff and will not absorb water. I think foam over carbon gives you the lightest, stiffest, and most water resistant hulls.

Foam retains its shape, so it doesnt want to lay in the hull molds, you need to either heat it or coax it in or both. Supposedly Vectorworks has this figured out and uses some combination of heat and pressure to get the foam to behave. I used a heat gun and weights. Not exactly scientific and it took forever.

Bill

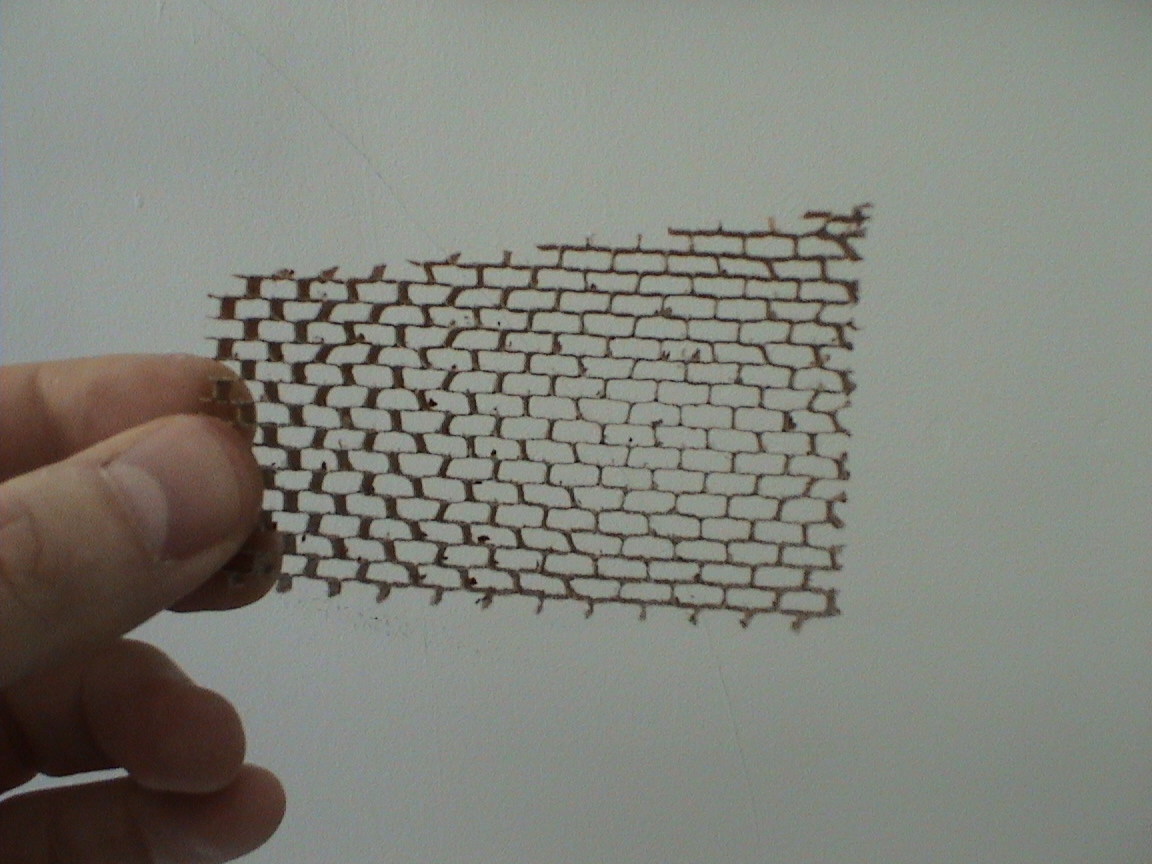

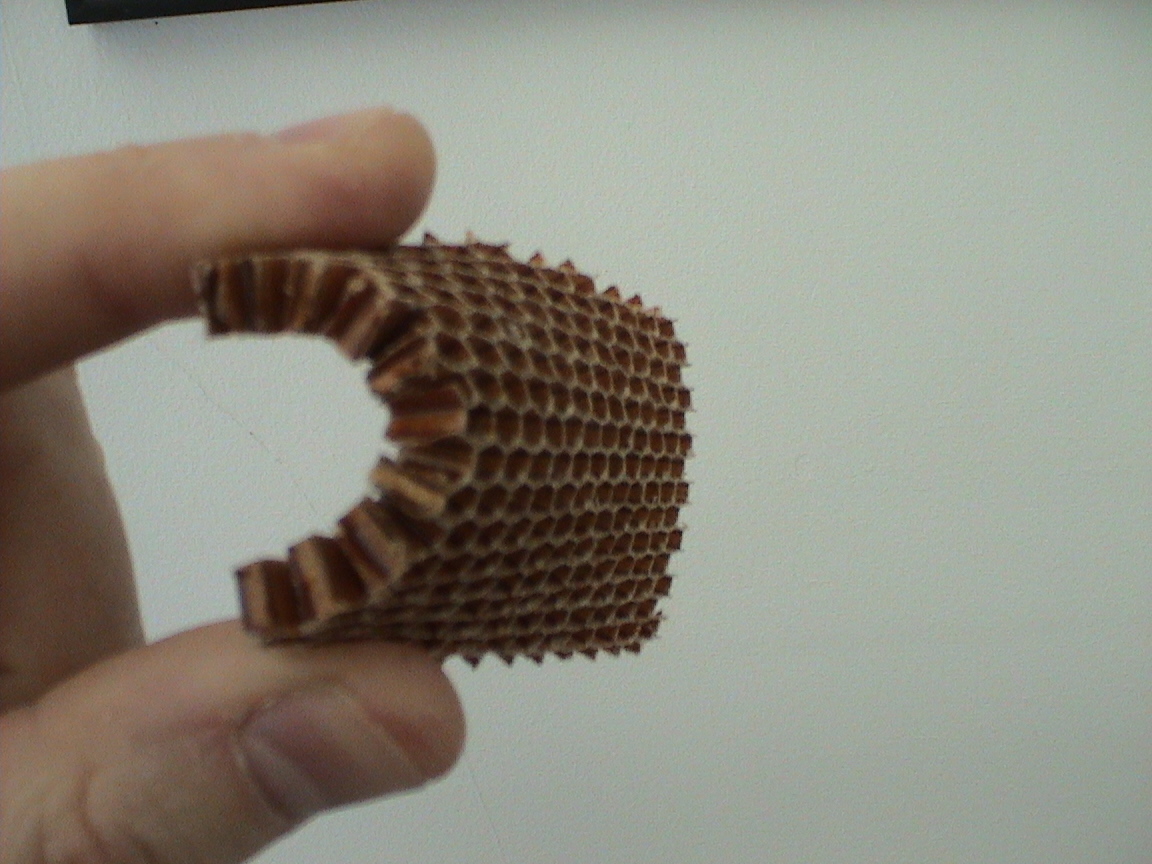

Posted By: bvining OX Nomex - 02/15/06 04:14 PM

A picture of ox nomex core.

Posted By: bvining Re: OX Nomex - 02/15/06 04:17 PM

Overexpanded honeycomb nomex bends easily in one plane and is rigid in the other.

Posted By: fin. Re: OX Nomex - 02/15/06 05:04 PM

Bill;

Thanks again. I'm looking at the XJ because it's close to home, but you just gave me even more reasons to go with Vectorworks.

Posted By: sailwave Re: A cats and carbon - 02/15/06 05:19 PM

Hi Bill,

> If its going to blow big, you will

> want to take your mast down.

Do you have a feel for the numbers..? I've been tying my (new to me) flyer down using the hulls and the trapeze wires and it seems ok in about 20mph. Last night we had 40mph forecast and so I took it down; but storage is a bit of a problem, and so I'd like to leave it up when I can... I'm not sure what my limit is though...

Also, what is the technique for taking the mast down solo. I have a hinge attachment to make it easier (see pics below) but have not successfully achieved it yet...

NB: your technical posts are great; keep em coming; I have to admit I don't even know specifically what my (AHPC) flyer is made of (other than 'carbon') - I just wanted a boat that was light, looked great and went fast

Some pics...

Some pics... Posted By: sailwave Re: OX Nomex - 02/15/06 05:36 PM

Hi Pete,

It's possibly just me, but I went for centre cleatless sheeting when I bought my A and just got tangled up! I've gone back to traditional rear cleated sheeting and feel much more at home (moved from F18). When I get used to the boat, I'll give it another go because the sheeting angle is in fact more comfortable, but I found it a handfull straight off... Just thought I'd mention it... Another alternative is cleated boom sheeting a-la Ben Hall I think...

Posted By: Anonymous

Re: A cats and carbon - 02/15/06 05:38 PM

Pete:

If you are going to spend serious money like me ($22,00 for a A2), get a storage unit inside. I pay $60 a month for a 10 x 20 unit. Yes I have to take mast loose and store in above the boat, but is is safe and out of the weather. Boat should look as good 5 years from now as it does when I get it.

Doug

Posted By: fin. Re: OX Nomex - 02/15/06 05:53 PM

Colin;

At this point I'm too ignorant to consider the matter!

Doug;

Good thinkin'! (that would solve some zoning issues I'm haveing trouble with)

Posted By: bvining Re: OX Nomex - 02/15/06 06:04 PM

Doug,

Yeah I agree, I keep my boats and masts inside in the winter and covered or inside in the summer. I'm toying with a covered trailer/box that I could slide the DK into and it would be protected from the UV and I could leave it more rigged for over the road.

How much wind is too much? If you are in an unprotected area I would take it down if its forecasted to be over 25-30knts. Usually a 30knot forecast is associated with some kind of weather system, so its not going to blow a steady 30, its going to be justy and probably blow 20-40, or 25-45, In a more protected area you would have to judge for yourself.

Colin,

I went with midboom sheeting, I'd rather have the sheet attached to something more solid than the tramp.

As far as whats your flyer made of? I dont know, it depends on the vintage. Could be kevlar/carbon combo, or carbon, or all kevlar. We could cut it open and see.....

You could probably email Goodall and ask. I heard they are going back to Kevlar.

Look at the inside of the hulls, black is carbon, yellow is kevlar, white is glass. The core material is hard to tell unless you can see a cross section. Smash it up and take pictures. Corecell foam is yellow, Divinycell is blue I think.

As far as if its epoxy or polyester, its hard to tell until you cut into it. Polyester has a sweeter smell than epoxy.

You should probably know what its made of so that you can be ready to fix it when (if) it breaks, its important to use the same materials so that your repair isnt harder or softer or more flexible or less flexible than the rest of the boat.

Bill

Posted By: Anonymous

Re: OX Nomex - 02/15/06 06:12 PM

If a twister or high straight line winds come it doesn't matter where you have your boat. That is what insurance is for!!I just like to have mine out of the sun and keep the mold off it. So nice just to put mast on and go. I ALWAYS wash the sand and salt off it before I put in up. My 87 rebuilt boat looks new.

Doug

Posted By: sailwave Re: OX Nomex - 02/15/06 06:17 PM

Hi Bill,

Thanks for the note.

> I went with midboom sheeting, I'd rather

> have the sheet attached to something more

> solid than the tramp.

I got used to the tramp pulling-up, but tacking, that was another thing entirely. I also found it difficult to hold upwind in anything other than the lightest of winds; but perhaps that was just the block because other folk seem to manage OK. I'll have another go at it some time in the future...

Posted By: bvining Re: A cats and carbon - 02/15/06 06:40 PM

Colin,

Your flyer base hinges in the front right?

I always tie the trap lines to the beam and it provides a hinge so the mast can only move front to back, not side to side. Remember to put the pin in the mast base.

Stick your wheels or something under the bows so that the mast is leaning back and the shrouds are not carrying any of the weight. Bows should be into the wind, so the combination of wind pressure and gravity should keep the mast from moving.

Undo the shrouds, and then lower the mast.

You could always rig a line with a slipnot that you could undo from the mast base, so you wouldnt have to leave the mast unattended, or you could get a stranger to pull the pins on the shrouds. Might be a good way to meet girls, "Excuse me, but could you pull on my pin? I mean...no wait come back...."

Posted By: Dan_Delave Polyester or Epoxy - 02/15/06 06:44 PM

You can tell the difference if there is a way to smell the inside of the hull through a porthole of even drain hole. If you have either (polyester or epoxy) sitting around you can smell a can of it and compare it to the boat. Each has a very distinct smell that is pretty close to their smell when wet. If you cannot tell the difference find someone who has worked with both. I think that Vinylester is a bit hard to tell from Polyester.

[color:"blue"]Stepping the mast solo[/color] on an A Cat is a snap. At my club unless it is the first time a mast is going up most of the sailors put them up solo anyway. Even if there is someone right there to help. Put the boat on Catwheels about 1/2 the way from the front crossbar to the tip of the bow. This way the boat is sitting on an angle back. Slack the forstays a bit (maybe 2 to 3 inches) but have them attached to the bows. Attach the hinged part from the base of mast to the front crossbar. Stand about the middle of the mast and lift. Walk hand over hand lifting the mast until it settles back on the forstays. Make sure that the boat is pointing in the wind. The mast will stand there by itself with the two forstays as supports. Then go to the shrouds and connect those. When you are done you will have to tighted up the forstays again.

The people at my club that step this way are Pete Melvin, Pease and Jay Glaser, Howie Hamlin and Jeremy Laundergan.

Later,

Dan

Posted By: sailwave Re: Mast lowering - 02/15/06 07:17 PM

Dan/Bill

OK thanks (yes, front hinge). I've been preparing for the drop right by the sound of it, but have not had the confidence enough to stand in front of the mast and walk back with it myself to lower it; still in F18 'everythings-heavy' mode perhaps! I'll give it a try next time with somebody a bit further back just in case

PS: hulls are late 2005 => kevlar/foam/carbon/vinylester.

Posted By: fin. Re: Polyester or Epoxy - 02/15/06 07:22 PM

Dan;

Please pardon my ignorance, but can you stand on the tramp when the boat is on the trailer or the beach wheels?

On my 16 and 17, I stepped the mast while it was still on the traier, no support for the hulls other that the rollers.

Posted By: bvining Re: A cats and carbon - 02/15/06 07:34 PM

Doug,

Did you price an XJ? The last price I remember was for a Bimare Italian made boat for $13,500 euros.

Any idea what a Vectorworks XJ costs?

When you get an A2, do you get a choice of sails? How about mast?

Pete, have you priced out the Vectorworks XJ? Whose mast or sails do they come with?

It would be interesting to compare/contrast two similar boats from two companies in the US.

Posted By: fin. Re: A cats and carbon - 02/15/06 07:44 PM

Bill:

Vectorworks quoted me $17k f.o.b. their factory, with no sail option. Bimare sail I believe, no idea who the sailmaker is.

They're supposed to getting a couple of '05s, that will be reworked and offered at $16k. I'm more interested in these boats. I'm figuring $1k will go a long way for a new sail in a year.

Still waiting to hear back on that.

Posted By: fin. Re: A cats and carbon - 02/15/06 07:48 PM

Bill:

I've also managed to get hold of a set of plans for ply construction that is not completely out of the question, though it is less desirable.

Posted By: bvining Re: Polyester or Epoxy - 02/15/06 07:49 PM

Pete,

The Flyer has a front mast hinge, so it hinges forward and you stand between the hulls to raise and lower it. I'm using a Flyer mast base, so my mast will hinge forward too.

The mast on an Acat is so light its very easy to lift, you dont need the leverage of standing on the tramp.

I'm pretty sure the XJ hinges forward, not sure about the the A2.

Most A cats support the boat on the trailer by the beams.

Bill

Posted By: bvining Re: Mast lowering - 02/15/06 07:51 PM

Colin,

I just looked at the pics of Phil Kinders crushed Flyer it looks like carbin inside skin, corecell foam and kevlar outside skin, with gelcoat.

Bill

Posted By: Rolf_Nilsen

Re: A cats and carbon - 02/15/06 07:56 PM

What design would that be? Pure ply or ply+carbon?

Just curious..

If you dont really want to build a boat but are thinking about it to save some money, dont build! Buy a used one (go to the bank, sell something or take an extra job to finance it) and go sailing instead.

Look at this one, not min. weight, but still..

E-baySpeaking about A's. Anybody know what competitive crew weights are?

Is there more information about this A-cat?

http://www.ashbysails.com/boats.html Posted By: fin. Re: A cats and carbon - 02/15/06 08:02 PM

Rolf:

All the used boats I've been able to locate are too far away, too old or both.

Posted By: Anonymous

Re: A cats and carbon - 02/15/06 08:05 PM

Pete:

Pete Melvin suggested I get Bob Hall to make me a spar based on my weight and sailmaker choice and have it sent to Performance Cat before they build A2. I am going with a Glaser sail because they won 6 out of 8 of the last N/A's and the Worlds. Here is a site for some A cat trailer ideas.

http://www.acatsnw.com/trailer/trailers.html I think I will get a Trailex double stack so I can mount A cat on when I want to take both 17 and A cat.

Doug

Posted By: sailwave Re: Mast lowering - 02/15/06 08:09 PM

Hi Bill,

> it looks like carbin inside skin, corecell foam

> and kevlar outside skin, with gelcoat.

Ta, you just saved me from smashing one of the hulls to find out; vinylester resin too according to the web site... So, thus armed with such technical knowledge I expect to go a lot faster on Sunday...

Posted By: Wouter Re: A cats and carbon *DELETED* - 02/15/06 09:25 PM

Post deleted by Wouter

Posted By: fin. Re: A cats and carbon - 02/15/06 09:31 PM

Thanks Wouter, but it's too late for #6

Posted By: Wouter Re: A cats and carbon - 02/15/06 09:38 PM

For some tricks stabilizing your mast in a blow go and do a search on the F16 forum. We've covered this topic several times overthere.

We all keep our masts up overhere on the beach, for 6 months without exception. F16's and A's

Wouter

Posted By: Wouter Re: Mast lowering - 02/15/06 09:45 PM

AHPC late 2005 ?

Most probably a full kevlar laminate hull.

Bill was looking at an older hull

Wouter

Posted By: bvining Re: A cats and carbon - 02/15/06 10:36 PM

Ok Here is Wouters post from the F16 Forum

I actually did a wrote up on securing the mast a while back, try a search on the forum. By now we have 7002 postings and I don't exactly remember when I wrote it down.

But in summary. The mast on the Taipan is not a stiff pole by any stretch of the imagination. You'll need to secure it very well for it to survive any harsh winds. Problem is not strength but resonance. Even a mild wind with the right exiting frequency can seriously vibrated that mast.

However I found that some very simple mods can make your mast totally resistant to anything the wind and weather can throw at it. I've tested it for many months out here on the beach at my local club and we had a few storms since then. Of course the platform needs to be tied down very well and rather tight, absolutely no slack may be in the tying down. The platform is only 55 kg and if it has room to move about then it will dig itself into more room and finally escape.

The mast when supported with only the three stays has a resonance frequency that is very common in normal wind patterns. Very bad for mast up storage. However if you use your mainsail halyard and spi halyard to stabilize the top of your mast in addition to using your mast rotation and boom to stabilize the rotation then you mast will stand straigh and still as a telegraph pole. By stiffening up your mast like this the resonance frequency has been place well outside the range that are encountered in wind of any type.

Roughtly

-1- tie teh start of your mainsail halyard off on the mast; the other end (which goes up and through the small block at the top) you tie off to the end of the boom near the outhaul line. Use the outhaul line to prevent the halyard from sliding along the boom towards the mast.

-2- Now use your mainsail traveller control line to pull the boom down. You do this but graping a loop (between the cleat and the car) and throwing this over the end of the boom. Now pull the traveller line tight and cleat it. Your mainsail halyard is now tight and pulls the top of the mast slightly backward. Also the boom and car are now centred and can't move to either side.

-3- Now pull in your rotation limiter towards the boom thus securing the mast in the way of rotation as the boom is well secured by the mainsail traveller line and cleat

-4- If you have a spinnaker setup then. Tie both ends of the spi halyard off to one another and pull the halyard through its cleat till the spi hayard is tight and its acts like a second foresay. This will go all the way up to the spi gate on the mast. Now the mast is completely secured in the fore and aft plane and the fixed rotation will prevent oscilations over its minor axis (side to side)

When things get really dicy then use the trapeze line to secure the whole boat to the ground in addition to the ties on the platform itself. If the mast can't move than the the platform can't either. I have adjustable trapeze line with a jam cleat and I use them to put some tension on the trapeze lines so the boat has absolutely no play anywhere.

I only use two tie downs for my platform. Coming up next to the hulls and I tie them off to my side stays. I then pull a peice of tough foam underneath the lines to get some real tension in them and to prevent the lines from rubbing on my hulls and layer of paint.

In the past I used to stabilize my spreaders with an extra line as well but found that that really wasn't necessary.

So my advice =

- 2 ties on the sidestays.

- Main halyard, boom, mainsail traveller line, mast rotation and spi halyard triangles to further secure the mast

- when required additional tie down using the 2 or 4 trapeze lines to fixed points on the ground neary

Fixed points in the ground must be really secure as the wind can pull out alot of simple stakes or poles. Easiest and best is just a planck or pole that is burried horinzontally at say 2 to 3 feet deep. Tie a line to the middle of it and use that as a secure point.

Good luck,

Wouter

--------------------

Wouter Hijink

Taipan F16 (one-off; homebuild)

The Netherlands

Posted By: Anonymous

Re: A cats and carbon - 02/16/06 12:25 AM

Pete:

If you decide to get a A2, Pete Melvin suggested I contact Ben Hall and have him make a spar based on my weight and sailmaker and have it sent to Performance Cat before boat was put together and add any extra support needed for a spinnaker.

Doug

Posted By: Acat230 Re: A cats and carbon - 02/16/06 01:37 AM

Colin's new Flyer is beautiful. It looks like he got it with the glued beam option and the execution of that looks quite good.

AHPC, A2, and Bimare are vinylester boats. Vinylester is stronger than polyester, a bit weaker than epoxy (but less toxic than epoxy). I think AHPC is using Nomex core based on the skin imprint I saw on my Mk. V but it may have been different for the Flyer. Marstrom and A2 both currently use Nomex.

I think first Flyers built by AHPC were all carbon but their website now lists construction as carbon and kevlar. My guess is Greg Goodall is now using an outer kevlar skin for impact resistance and inner carbon skin for stiffness and strength. My previous Mk. V was all Kevlar construction and had more more bulkheads than the Flyer (which has only 2). I don't think it gave away anything in platform stiffness.

Marstrom platform (epoxy pre-preg, Nomex core, autoclave cure) is probably the strongest construction. Others are vacuum bagged with the resin infusion system used on the A2.

Many have thought the best competitive weight range for the A-cat is 160-185 lbs but I've seen light sailors like Pease Glaser finish quite well in 14-16 knots of wind and bigger sailors like Woody Cope and Doug Graf finish quite well in light air. It's still about time in the boat and getting your rig and sail trim numbers right no matter what the platform. All of the recent platforms including the A2, Marstrom, Flyer, XJ, Auscat Mk. V, and Auscat Mk. IV are capable of winning races which is a good thing for the class. We don't see any significant performance improvements in hull design in the near future. We think more performance evolution (that will be subtle at best) will continue with sail planforms and foil plans and shapes.

If you get into the class and want to win races, you still have to get out and sail the boat and sail the boat a lot

.

Bob Hodges

A2 USA 230

Posted By: fin. Re: A cats and carbon - 02/16/06 01:48 AM

Bob:

Thanks very much, hope to be on the water soon.

Posted By: Anonymous

Re: A cats and carbon - 02/16/06 01:56 AM

Bob:

Was nice meeting you this weekend. Yea I can't wait to get the A2 and get time on the water. Hope to see you at Deep South, if not maybe Wayward winds.

Doug Snell

Posted By: sailwave Re: A cats and carbon - 02/16/06 08:17 AM

Hi Bob,

> Colin's new Flyer is beautiful. It looks like he

> got it with the glued beam option and the execution

> of that looks quite good.

Piet Saarberg did that. He imports the hulls then glues them using a custom made jig. The boat has Saarberg foils and hull tweaks done by AHPC to take his narrower dagger boards; I believe his rudders are slightly thinner too.

I've always liked the idea of an A Class and it is everything I'd hoped for. I work pretty strange hours, so I'm looking forward to the Summer when I can go sailing in the day without searching around for a crew...

Thanks for the info...

Posted By: Wouter Re: A cats and carbon - 02/16/06 11:26 AM

Here some updates :

I think first Flyers built by AHPC were all carbon but their website now lists construction as carbon and kevlar. My guess is Greg Goodall is now using an outer kevlar skin for impact resistance and inner carbon skin for stiffness and strength.

Full kevlar hulls are produced significantly more lately. There are various reasons for that. That is all I can say at this moment.

Marstrom platform (epoxy pre-preg, Nomex core, autoclave cure) is probably the strongest construction. Others are vacuum bagged with the resin infusion system used on the A2.

AHPC has been using infusion for a while now. Nacra makes a big fuss about their boats being the first to use resin infusion (especially with the F18 infusion) but they are just wrong. Several other were already using this methode even in the F18 class.

WOuter

Posted By: Catfan Re: A cats and carbon - 02/16/06 02:39 PM

Pete

BIMARE sails are made by "Bim sail", the internal sail-loft of BIMARE. Differently from other catamaran builders such as Hobie Cat, which have sails made by "external" sailmakers with their logo, BIMARE has been producing for over 30 years all the mainsails and asymmetrics which fit its range of unirigged boats "in house".

Have a look at:

http://www.bimare.net/saile.htmThe development of Bim sails is carried out by Valerio Petrucci, the elder son of BIMARE founder, and other top notch Italian A catters.

Moreover let me add that they are not too bad:

in 2005 they got a 6th at the A Class Worlds, a 1st at the Italian National, a 3rd at the German Nationals.....

Posted By: Acat230 Re: A cats and carbon - 02/16/06 02:42 PM

Colin,

Regarding the pictures of your boat, the tramp looks extremely clean. How are you leading the tails of the rotator control and downhaul? In the pictures, it looks like they are led under the trampoline. Mine are kept on the top of the boat which is not as clean.

Again, beautiful boat!

Bob Hodges

Posted By: bvining Re: A cats and carbon - 02/16/06 03:40 PM

I highly recommend the Hall Spar, they will make you a custom mast based on your weight, and the amount of fore and aft bend specified by your sailmaker. This along with your sailmakers specs on prebend, spreaders, etc should get a very nice mast/sail combo.

Posted By: sailwave Re: A cats and carbon - 02/16/06 03:54 PM

Hi Bob,

Regarding the pictures of your boat, the tramp looks extremely clean. How are you leading the tails of the rotator control and downhaul? In the pictures, it looks like they are led under the trampoline. Mine are kept on the top of the boat which is not as clean.

Again, beautiful boat!

She is pretty...! In the photos, the control lines are coming from the cleats through the tramp eyes and then tied together underneath across the boat. I tried variations on this theme including using bungee to take up the slack but they still end up getting trailed in the water at some point (lots of downhaul for example). I think I need to splice bungee to the lines such that the join will go through a block - then it can all be hidden under the tramp by routing to the opposite diagonals a few times. Actually I was going to ask what method you more experienced sailors find best...?

It's a bit weird having such a simple boat after the F18, but it is quick to rig! Piet S always goes for the simple option if there is a choice; for example my outhaul just has a knot in the end of it that feeds into a simple little strop - I never thought it would work, but it does...

Posted By: sparky Re: Polyester or Epoxy - 02/16/06 04:03 PM

Stepping the mast solo on an A Cat is a snap. At my club unless it is the first time a mast is going up most of the sailors put them up solo anyway. Even if there is someone right there to help. Put the boat on Catwheels about 1/2 the way from the front crossbar to the tip of the bow. This way the boat is sitting on an angle back. Slack the forstays a bit (maybe 2 to 3 inches) but have them attached to the bows. Attach the hinged part from the base of mast to the front crossbar. Stand about the middle of the mast and lift. Walk hand over hand lifting the mast until it settles back on the forstays. Make sure that the boat is pointing in the wind. The mast will stand there by itself with the two forstays as supports. Then go to the shrouds and connect those. When you are done you will have to tighted up the forstays again.

The first time I set up my boat by myself, this is exactly the process I used, right up until I was about to put the pin in the last (port) shroud. I was trying to make sure the shroud was not tangled in the trap line when a gust came from a different direction and took the mast forward and dropped it over the top of my starboard hull, destroying the mast.

I thought I would explain this so you might also like to do something to stabilize the mast (trap line to the rear beam or traveler?) once you get the mast up and until you can get both shouds attached.

I was devistated, as I had never sailed the boat! I purchased it after Pete Melvin had won the 2004 North American Championships on it in Traverse City, Michigan in September. This was the first Nacra A2 and I trailered it to Annapolis for Boat of the Year evaluations. Thank God that Tony Ahrens (Racer X Sails) loaned me his mast and sail for those trials, and the boat subsequently was awarded Boat of the Year.

Posted By: GISCO Re: Polyester or Epoxy - 02/16/06 04:35 PM

I run a small line around the front of the mast through the tang on the hulls to the shrouds. When the mast is raised I pull them tight and tie them off so I can go around to pin them without the mast accidently coming down. Also it keeps the shrouds from swinging about and getting tangled up as you raise the mast.

Posted By: Dan_Delave broken parts from a falling mast - 02/16/06 06:12 PM

Sparky:

Sorry to hear about your accident. For a safety you could tie the shrouds to the cross bar at the hull while lifting. This would keep the lateral forces out of the equation. As the mast goes up those lines will just act to keep the mast in the center. If you would like to take the safety to the next level you could loop a line on a trapeze handle. Run that line back around the rear crossbar, under the boat and back to the front. When the mast is up you pull the line tight and tie it somewhere convenient to where you are (at the front crossbar). This will give you a nice three point stance for the mast. I think this is what Gordon was saying. Then you will have plenty of time to attach shrouds as the mast will go nowhere. I think that this whole plan will take no more than about an extra 2 minutes to implement.

Later,

Dan

Posted By: Jalani Re: A cats and carbon - 02/16/06 06:30 PM

Colin,

I route control line tails on the Stealth through eyes or blocks and take up the slack by sewing bungee onto the ends. There is no real downside to this as you just have to think through where/how you can dereave the lines when derigging. The upside is that everything is neat and tidy. The two exceptions on my boat are the trapeze return bungees which are simply knotted to the trapeze lines and the main downhaul which is on VERY small S/S hooks that pass through the mainbeam endcaps.

This is because I found that I have to take off ALL the tension on the purchase to be able to unhook the tack of the main.....

The only thing I still have left to do is create a tunnel under the tramp (in tramp material) to tidy up the underside.

As you've already spotted, taking up the slack on large purchase systems (downhaul etc) requires a lot of bungee!

See you at Mumbles during the F16 Nations Cup?

Posted By: sparky Re: broken parts from a falling mast - 02/16/06 08:15 PM

Thanks Dan! Good ideas! I like the idea of running a line through the trap handles and feeding it around the rear beam and under the boat so I can tension it when I have the mast up. This is similar to what one of our club's sailors did when raising the mast on his N5.5 Uni. He supported the end of the mast on a simple tripod in front of the boat, put the bottom of the mast on the pivot ball and put the pin in. When he raised the mast, he took up the slack in the safety line (these went through the trap handles and kept them out of the way of everything else) to hold the mast in place until attaching the side stays. Then he removed the safety line and attached the trap line to the bungees and he was done! He always did the process single handed. I should have learned!

I don't feel too bad about the mast because insurance took care of getting a new one (less deductable) and I had it before the next sailing season started.

Posted By: bvining Re: broken parts from a falling mast - 02/16/06 09:16 PM

Les,

Did you get to keep the old mast?

Can I have it? Did it break right in the middle?

Bill

Posted By: sailwave Re: A cats and carbon - 02/16/06 09:21 PM

Hi John,

Definitely going to try that (sewing) - it'll make a really neat tramp... something I've noticed on other As is routing the downhaul to a block on the shroud before going into the tramp hole; presumably so it's a little closer to hand; it also means you can pull post-block and you know it's going to stay cleated...

> See you at Mumbles during the

> F16 Nations Cup?

I'll be there - if I can't disguise the A as an F16, I'll be in the bar...

Posted By: Wouter Re: A cats and carbon - 02/16/06 10:37 PM

Posted By: sparky Re: broken parts from a falling mast - 02/17/06 05:46 PM

Bill,

I still have the mast. You cannot have it (well, maybe, for the right price). I have a friend who used to build DN masts and he looked at it and thought we could make a pretty good back-up mast from it.

It broke closer to the base than the top. It is a Hall spar and is mostly unidirectional carbon in the area, so most of the breaks are multiple splits going vertically, lots of vertical splits. I thought about making trophies out of the tube (I already removed all the hardware and have purchased another Hall spar to build into a spare mast), but after talking to my friend, I may repair the damaged spar, reassemble it for a spare, and sell my undamaged spare Hall spar. I haven't decided yet.

Posted By: bvining Re: broken parts from a falling mast - 02/17/06 06:06 PM

I was thinking it would make a good moth mast.

If you decide to sell it, let me know.

Posted By: sparky Re: broken parts from a falling mast - 02/17/06 06:43 PM

How long is a Moth mast? I will measure the undamaged length to see if it would work.

Posted By: bvining Re: broken parts from a falling mast - 02/17/06 07:13 PM

Moth

Max mast lenght is 6.250m

8m2 max sail area.

Max luff 5.185m

Posted By: bvining Re: broken parts from a falling mast - 02/17/06 07:16 PM

If it was me, I'd fix it and keep it as a spare. if you do decide to cut it up, I'll make you an offer on it - before you chop it into little sections.

I bet the bend charactoristics would be too far off for a DN mast, thats a very unscientific judgement based on how much DN masts seem to bend. Would the A cat mast bend that much without breaking (again)?

Posted By: Anonymous

Re: broken parts from a falling mast - 02/17/06 07:30 PM

Les:

Going to get Ben Hall to make me a spar based on my weight with I order A2. How do you like it?

Doug Snell

Hobie 17

Soon to be A2

www.tcdyc.com check out our site guys

Posted By: bvining Re: broken parts from a falling mast - 02/17/06 08:15 PM

Les,

How about a trade

Bill

Posted By: fin. Re: A cats and carbon - 02/18/06 01:46 AM

Bill:

Did you get the email about Bimare's new 11 meter autoclave?

Posted By: Anonymous

Re: A cats and carbon - 02/18/06 02:11 AM

Pete:

Did you get the video I sent you on Javelin?

Doug

Posted By: fin. Re: A cats and carbon - 02/18/06 02:47 AM

Doug:

I did get the Javelin video; and sent it to every one I know!

Posted By: Anonymous

Re: A cats and carbon - 02/18/06 02:53 AM

Glad you liked it. If you are buds find any A2 videos, let me know.

Doug

Posted By: Jake Re: A cats and carbon - 02/18/06 02:58 AM

ummm....helllo. videos please. I'm dying here being drowned in 29'er videos with my cohort at work...I need some ammo.

Posted By: Anonymous

Re: A cats and carbon - 02/18/06 03:06 AM

What kind do you want? If you want the A cat Javelin. Sent me a email link.

www.thebeachcats.com has some good ones. 3 Amigos on our site is good.

www.tcdyc.com You will have to register to get them.

Doug Snell

dsnell4 at houston dot rr dot com

Hobie 17

Soon to be Nacra A2

Posted By: fin. Re: A cats and carbon - 02/19/06 02:53 PM

I have it on good authority that A cats can be trailered safely in cradles and that supporting them at the crossbars is not absolutely necessary.

Comments please.

Posted By: bvining Re: A cats and carbon - 02/20/06 03:10 PM

Peter Johnstone dragged his XJ to Florida and back on cradles, but he had some foam padding between the cradles and the boat.

Posted By: bvining Re: A cats and carbon - 02/20/06 03:18 PM

Posted By: fin. Re: A cats and carbon - 02/20/06 03:19 PM

. . .foam padding between

Good idea!

Posted By: bvining Re: A cats and carbon - 02/20/06 03:21 PM

Phil Kinder made him some sweet cradle covers with foam that fit over the standard cat cradles.

http://www.kinder-industries.com/Phil also makes really nice whole boat covers for A cats, and tramps too.

Posted By: sparky Re: broken parts from a falling mast - 02/21/06 11:01 PM

Bill,

Undamaged length of the Hall Spar is 21' 7.5", but there is an area that had been repaired by Melvin up near the hounds included inside that length.

Posted By: sparky Re: broken parts from a falling mast - 02/21/06 11:08 PM

Doug,

I LOVE my A2! I weigh 182# naked first thing in the morning after going to the head (lightest I ever am

). I use the medium stiffness spar from Hall and this is the one recommended by Pete Melvin and happens to be the stock A2 mast from Performance when I bought the mast from them.

I am finding the leaqrning curve to be much steeper than any of my other boats (H16, 18 Square, N5.5Uni, Inter 17R) and am stuggling getting up to speed downwind. I can't seem to get the angles right, and am realizing that I need to head up some to be competitive in Portsmouth racing. Unfortunately, I haven't had much opportunity in my first year on the boat to sail head-to-head with many A Cats.

Posted By: sparky Re: A cats and carbon - 02/21/06 11:12 PM

I have it on good authority that A cats can be trailered safely in cradles and that supporting them at the crossbars is not absolutely necessary.

Comments please.

Pete Melvin recommended to me that I use cradles in lieu of supporting from the crossbars, so that is what I do. No problems with mine so far, but only have trailered it this way for about 3000 miles.

Posted By: Anonymous

Re: A cats and carbon - 02/22/06 12:58 AM

Les:

I am pretty much sold on the A2. Pete Melvin told me to contact Ben hall and have him build a spar to my weight. We have a local hotshot at 250 that is deadly, but has LOT of time on the boat. Bob Hodges and Bob Webbon both said you just need a LOT of time on the boat. Christopher and I are working out a spinnaker system using a homemade snail from Bill and working on pole system. I want it to play with until maybe later the class starts using them. If not be fun to play and in Portsmouth races on Wed nights

Doug Snell

Hobie 17 with reacher and squaretop

Soon to be Nacra A2

www.tcdyc.com Posted By: sparky Re: A cats and carbon - 02/22/06 01:26 AM

Doug,

I was at Performance Catamaran a couple of weeks ago and saw all the new stuff they have for the A2 since mine was built. The beams are clear coated, new molds for the rudders and dagger boards, and new dagger board trunks that have slots in them for up haul and down haul lines! Wow, would it be nice to have the ability to bring up and down the leeward board from the windward side! I think it is the best boat in the world, but I admit that I am biased!

I spent some time thinking about rigging a spinnaker for my A2, but decided that it is not the right thing for me. Don't get me wrong, I really enjoyed sailing the I 17R for 5 seasons and learned spinnaker sailing and even enjoyed downwind more than upwind. But I have been trying to get the downwind technique right on the A2, and when I seem to hit it right, the boat really flys! The A2 is much more exhilarating than my I 17R, 18 Square, or any other of the cats I have owned. It is VERY sensitive to down haul, mast rotation, and out haul. I think it will take me a LOT longer to get close to the potential of this boat than it took me on any of the others. That being said, with only one season on the A2, I can already think of things I would do different on all of the other boats I have owned. The feedback of what changes you make to the mast and sail is so direct and immediate that I think differently about what is the priority in changes to the "engine" of any sailboat. All in all, I am really happy with the stock A2 and think I will get the most enjoyment trying to get the most out of the stock setup, rather than adding the spinnaker (or any other modifications) to the A2. This is where I came out on the whole issue of adding the spinnaker (and I spent all last winter thinking of how I would do it!). Just mt 2 cents.

Posted By: Anonymous

Re: A cats and carbon - 02/22/06 01:40 AM

Les:

I will still will sail the boat a lot stock, just want the option as i have never sailed a spin on cat

May want to join these if you aren't already.

http://groups.yahoo.com/group/HoustonACat/ Although local may have some good info later.

http://www.usaca.info/Doug

Posted By: bvining Re: A cats and carbon - 02/22/06 01:00 PM

Les,

Can you take some pictures of the new uphaul and downhaul systems on the daggers?

Thanks

Bill

Posted By: sparky Re: A cats and carbon - 02/23/06 02:27 AM

Bill,

I have only seen the boards and daggerboard trunks and heard Jack Young tell me about it. I did not see any boats completely assembled, as they are shipped from the factory disassembled. Maybe someone reading this has an A2 with this feature...anyone?

Posted By: Dan_Delave Re: A cats and carbon - 02/23/06 05:30 PM

![[Linked Image]](http://catsailor.com/gallery/albums/userpics/10093/Daggerboard%20Control.jpg)

There are two lines attached to the daggerboard. One at the top to pull the board down and one above the bottom of the hull, so as not to drag in the water, to pull the board up. Those lines are run to opposite sides of the boat so you have control of them where you need it.

Posted By: Rolf_Nilsen

Re: A cats and carbon - 02/23/06 06:00 PM

Ok, but when does it pay off to use them?

Posted By: scooby_simon Re: A cats and carbon - 02/23/06 09:22 PM

Rolf,

I't just means the leaward plate can be raised (the depth of the hull)/lowered(fully) without going over there which can be exciting single handed when windy.

Posted By: Rolf_Nilsen

Re: A cats and carbon - 02/23/06 09:37 PM

Simon, I understand this.

To rephrase, under what conditions and on which courses do the A-cat class find it beneficial to raise one daggerboard?

There has to be a quite large advantage to having this system onboard, as it clutters up the boat, adds weight and complexity. I could guess based on my own experience and knowlegde, but would like to hear the fasit.

Posted By: Wouter Re: A cats and carbon - 02/23/06 11:46 PM

Here a picture of the system as seen on a Taipan 4.9 (F16)

![[Linked Image]](http://www.catsailor.com/bb_files/67949-ahpc_taipan49_daggerboard_sheeting.jpg)

Rolf, the system is handy when singlehanding. With one short and sharp pull perpendicular to the line both boards can be pulled up or pushed down. It is handy when rounding a crowded mark. In the picture only the uphaul line is fitted.

Alot of crew want to pull up their board when transitioning from upwind work to a reach or downwing leg; this tends to calm the boat down. Boats with long daggerboards can feel trippy on these courses with a fully set board.

Wouter

Posted By: catman Re: A cats and carbon - 02/24/06 02:40 AM

Seems to me when sailing in areas that have grass it would be quite nice to be able to cycle the leeward board without having to go there.

![[Linked Image]](http://catsailor.com/gallery/albums/userpics/10093/Daggerboard%20Control.jpg)

![[Linked Image]](http://www.catsailor.com/bb_files/67949-ahpc_taipan49_daggerboard_sheeting.jpg)