Catsailor.com Mast Repair

Posted By: davefarmer Mast Repair - 04/09/06 07:07 PM

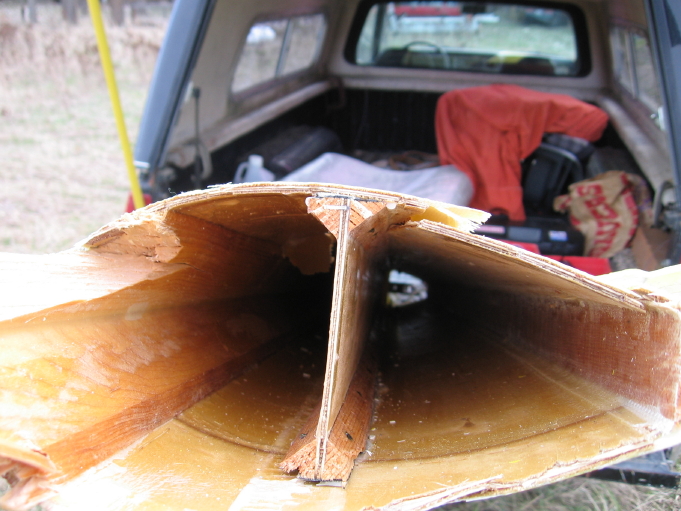

OK, Wouter has got me thinking seriously about repairing/reinforcing this wingmast. I'd love more input on techniques to use, people who might undertake the work, and more thoughts on why this failed where it did (compression failure?), and whether the design is sound enough to warrant the effort. I'll try to attach a few pics, and would be more than willing to send them to anyone interested in offering advice. Thanks so much!

dave

Posted By: davefarmer Re: Mast Repair - 04/09/06 07:18 PM

another pic

Posted By: davefarmer Re: Mast Repair - 04/09/06 07:34 PM

one more

Posted By: basket.case Re: Mast Repair - 04/09/06 11:57 PM

build a carbon one. it is easy, and lighter.

Posted By: Jake Re: Mast Repair - 04/10/06 12:57 AM

How did it break? Describe the conditions, what was happening at the moment, were you in a jibe, tacking, coming off a wave?

Do you have a spinnaker (was it up?)? Any number of things could have caused it to break - it looks like it broke 4' up from the base? Is that correct?

Posted By: davefarmer Re: Mast Repair - 04/10/06 05:48 AM

Had been sailing for 2 hrs, 10 to 12 knots of wind, gusts 15 absolute max. Flew a hull 6" off the water a couple of time. Boat felt great! Had been upwind and down a couple of times, did run the spin, but did reach with the screacher few times. Checked the diamonds several times, always finding the mast in column.

Mast broke shortly after heading back upwind. The boom has an underside traveller (ala 18 meter square) for the mainsheet between the rear traveller and the boom, so there is zero resistance from the mainsheet to the compressive forces the boom applies to the mast. I could see the boom flexing maybe 3" out of column(10' boom, big squaretop EP main), the mast rotation limiter was on pretty tight because the builder, Malcom Davy, had expressed his concern earlier that the boom was putting a lot of pressure on the mast. The mast is quite well reinforced at the gooseneck, and he feels that the forces were transmitted up the mast to the first weakest point. The break is 6' above the base, 36' mast, hounds 7' from the top of the mast, aft swept spreaders. Malcom said he'd had the boat out in 20 kt conditions before, had flow a hull close to vertical, so he'd put more force to the rig than I did.

What do you think?

Dave

Posted By: davefarmer Re: Mast Repair - 04/10/06 05:50 AM

What do you think a carbon wing mast woud cost? Materials alone?

Dave

Posted By: Wouter Re: Mast Repair - 04/10/06 10:04 AM

Personally I don't like this comment :

the mast rotation limiter was on pretty tight because the builder, Malcom Davy, had expressed his concern earlier that the boom was putting a lot of pressure on the mast.

Reducing mast rotation only puts the mast under higher stresses. If you are fearful than more rotation is the better option.

Wouter

Posted By: macca Re: Mast Repair - 04/10/06 11:49 AM

What made you tink that a hollow wooden mast would be strong enough in the first place??

I have a carbon wingmast on my taipan and it must be very close to its design strength cause there are times when it looks very ugly up there whan the kite is up. But to build one out of wood is just insane!

use the old wooden one as a plug for a carbon mould, then you will have a good mast

Posted By: basket.case Re: Mast Repair - 04/10/06 12:27 PM

What made you tink that a hollow wooden mast would be strong enough in the first place??

I have a carbon wingmast on my taipan and it must be very close to its design strength cause there are times when it looks very ugly up there whan the kite is up. But to build one out of wood is just insane!

use the old wooden one as a plug for a carbon mould, then you will have a good mast

i had a ply one on my boat for years. replaced it as i came into a bit of cash. heavy but strong and stiff. these things have been about years longer then carbon ones. west has been designing them almost for ever.

Posted By: Marcus F16 Re: Mast Repair - 04/10/06 12:48 PM

Ply core would be ok for mast construction, but there does not look like there is much glass work included, let alone any carbon.

There needs to be a balance in the composite layup - have you ever seen a multi storey building stand up for long becuase they used more concrete than reinforcing steel??

My observation is not enough glass/carbon to support the ply structure & timber structure.

It looks like the ply webs with fillets may have stopped at this point or did you cut the broken section to make it clearer viewing.

marcus

Posted By: sparky Re: Mast Repair - 04/10/06 02:09 PM

I would consult the Gougeon Brother (West System Epoxy) before doing anything with your current mast. They have done many wooden wing masts. They are located in Bay City, Michigan.

Posted By: steveh Re: Mast Repair - 04/10/06 03:05 PM

I don't think that I'd try a repair until the I understood the cause of failure and even then I'm not sure I'd trust a repair done at a point that failed. The big problem that I see is that you can't stagger the scarfs of the wood strips, so now you'd have a two scarf joints at the failure point.

In the first picture, is the dark line running from the leading to trailing edge a couple inches below the end of the web a scarf joint? Also, in picture 3, it looks like there is another dark line running from leading to trailing edge on the upper side just below the break.

"...the forces were transmitted up the mast to the first weakest point."

It doesn't work that way. The vast majority of the boom compressive force is taken up by the mast step. If the force from the boom is 100lbs, the mast is 36ft long and the gooseneck is 1ft above the step, then 97lbs of the load is transmitted to the mast step.

Posted By: davefarmer Re: Mast Repair - 04/11/06 02:08 AM

This one is a Barlow design, constructed using guidelines gleaned from a article on a similar mast built by the Gougeon Bros, using high quality materials and West System epoxies. Builder said it weighed 85 lbs, which I believe. Only 2 layers of fairly light E glass to sheath the outside. From what I can see, the quality of the construction looks good. The central web has separated from the mast sidewalls some near the break, but it's hard to determine whether it was there before the fracture, or a result of it. Maybe it's too light?

Dave

Posted By: davefarmer Re: Mast Repair - 04/11/06 02:16 AM

Reducing mast rotation only puts the mast under higher stresses. If you are fearful than more rotation is the better option.

Wouter [/quote]

Wouter, care to expound on this a bit more? I would think that the more the mast was aligned with the centerline of the boat, the stronger it would be. Isn't it stronger fore and aft, than side to side? Mast is 9" x 4.5". Mast was rotated maybe 60 degrees at the time of the break. Thanks!

Dave

Posted By: davefarmer Re: Mast Repair - 04/11/06 02:20 AM

build a carbon one. it is easy, and lighter.

Tell me more, especially about the easy part. Cost estimate for materials? Designs? Appropriate reading materials? I'm open to everything....

Dave

Posted By: davefarmer Re: Mast Repair - 04/11/06 02:44 AM

Ply core would be ok for mast construction, but there does not look like there is much glass work included, let alone any carbon.

My observation is not enough glass/carbon to support the ply structure & timber structure.

It looks like the ply webs with fillets may have stopped at this point or did you cut the broken section to make it clearer viewing.

marcus

There are 2 layers of fairly light E glass sheathing the outside of the mast, carbon was used at high stress points, tang, gooseneck, base, spreaders and diamond wire attachment points. The ply web with spruce gussets extends the entire length of the mast, it appears to have sheared pretty cleanly at the break. If you look close though to one of the pics of the break, there's a monel staple that appears to be across the plies of the web, which could only be if there was a joint in the web there. Malcom said all the joints in the web (and elsewhere) were scarfed, and the break in the web isn't a machined edge, so the whole thing is mysterious to me.

So a couple of questions come up around the repair. It would be nice to sleeve the inside of the mast somehow, as well as reinforcing the exterior. But not clear how to pull that off. And then there's the issue of how and how much to add to the exterior. I think Wouter is suggesting vertical tapes of unidirectional carbon fiber spaced around the circumference. Additonal layers of E glass or carbon cloth? The builder is suggesting that moving the forward attachment point for the boom off the mast to the main crossbeam will substantially reduce the point load on the mast, and I plan to do that. I need as much advice as you guys can give me!

dave

Posted By: davefarmer Re: Mast Repair - 04/11/06 03:21 AM

I don't think that I'd try a repair until the I understood the cause of failure and even then I'm not sure I'd trust a repair done at a point that failed. The big problem that I see is that you can't stagger the scarfs of the wood strips, so now you'd have a two scarf joints at the failure point.

Yeah, that bothers me too. I'm trying to figure out how to cut back the mast wall skin to allow me to get deeper into the mast sections to stagger the scarfs, particularly the leading and trailing edges.

In the first picture, is the dark line running from the leading to trailing edge a couple inches below the end of the web a scarf joint? Also, in picture 3, it looks like there is another dark line running from leading to trailing edge on the upper side just below the break.

You're right. Both of those dark lines are scarf joints in the ply sidewall material. One is 2" below the break, the other is within a 1/2" of the break. The solid wood at the leading and trailing edges have no scarfs within sight. The web, and it's solid wood gussets appear to be broken, but it's not completely clear that there was not a joint there (see note elsewhere about a staple runnung across the grain of the plywood web). The outside of the gussets has a carbon tape running vertically the entire length of the mast, and Malcom said the tricky part of assembling the mast was properly locating the web as the 2 halves were laid together. It's possible that there was an insufficient amount of thickened epoxy between the web and the mast sidewalls in this (and other?) areas. They are separated in this vicinity now, hard to tell if it was prior to the break, or as a result of the break.

"...the forces were transmitted up the mast to the first weakest point."

It doesn't work that way. The vast majority of the boom compressive force is taken up by the mast step. If the force from the boom is 100lbs, the mast is 36ft long and the gooseneck is 1ft above the step, then 97lbs of the load is transmitted to the mast step.

Gooseneck is 18" above the mast step, and the builder said he replaced the original mast step (delrin ball on 1.5" s.s. post) with a stouter version, as a result of the first one bending. That, coupled with my observation of the substantial amount of boom flex, makes me real aware of the amount of force the boom is applying here.

I agree wholeheartedly to the importance of understanding the reason for failure before investing in a repair. I really appreciate all the insight, questions and opinions being offered here. I'm happy to send higher quality pics directly to anyone wishing to help me explore this further. It's a gorgeous mast that I'd love to salvage if it seems feasible and justified.

dave

Posted By: Jake Re: Mast Repair - 04/11/06 05:33 AM

Wood masts are a bit out of my area of experience...but I do know that if you move the boom to the main beam that you will loose the forward pressure that rotates the mast. You will need to have some sort of positive rotation device (which can be tricky and lead to additional failure if not adjusted properly while tacking). I would think it better to adjust the vertical angle of the mainsheet to control the amount of compression applied to the boom...imagine if you will, if your mainsheet were perfectly vertical, there would be no more compression on the boom and very little induced loading on the mast (although you have the same lack of rotation problem as with a beam mounted boom). There is a happy medium where the mainsheet induces just enough forward pressure to ensure proper mast rotation and you can achieve this by either relocating your traveler or the point at which the mainsheet attaches to the boom.

Posted By: Wouter Re: Mast Repair - 04/11/06 08:12 AM

That, coupled with my observation of the substantial amount of boom flex, makes me real aware of the amount of force the boom is applying here.

I don't think the boom is excerting much force on the mast at all. How large was the sweptback angle of the mainsheet blocks when the mast broke. If it was almost vertical then the boom axial loads will have been rather small indeed. I think the boom flexing was caused by the mainsheet and clew corner not being in line with eachother. This created a bending laoding on teh end of the boom which bend it over its full length. Was the boom flexing downward ?

Wouter

Posted By: Wouter Re: Mast Repair - 04/11/06 08:20 AM

Mast is strongest in fore-aft plane and the loads on the mast are highest in the sideways plane. So more rotation will bring the strong plane of the mast more in line with the plane of highest loads. Pretty the forces on the upwind leg are the highest and here the sideways forces are 3 to 4 times as large as the fore-aft forces.

In reply to mast rotation. In big winds the way the stays are attached to the mast also help rotate it. This means that the amount needed to properly rotate the mast can be pretty small. In light winds you need the mainsheet to keep the mast properly rotated but here the mast loads are way lower. So in general the load from the boom (with an adjustable mainsheet angle as you have) can be considered pretty small. Unless you trim the mainsheet angled way back adn have the rotation limiter take up alot of load.

Wouter

Posted By: Wouter Re: Mast Repair - 04/11/06 08:23 AM

Macca,

There are quite a few hollow timber/glass/resin masts out there. Most of them on larger multihulls like this one.

It is definately not a rare occastion and they tend to hold up well.

Wouter

Posted By: Wouter Re: Mast Repair - 04/11/06 08:42 AM

I'm proposing horizontal rings (loops) of unidirectional fibre cloth (glass or carbon) around the circumference of the mast so the fibres run perpendicular the to length of the mast (the vertical). It is very important that you understand this correctly. Having the fibres aligned along the vertical will screw up the bending characteristics. The perpendicular (horizontal) loops will hardly affect bending.

Personal I would just make a sleeve on the inside and glue both parts to it and laminate the outside. I'm not the experienced guy in this aspect but I guess steaming some ply into shape will go a long way to make the sleeve. You will have to cut out the damaged ends and insert an new section here.

Most easy method I can think up (but I'm not the most experienced at this) would be to find some 1 mm thick ply steam the first one and bend it into the end of the mastsection. Then add more layers of 1 mm ply by bending it over the first one (steaming) and glueing them into place. This way you can build up any thickness of wall by adding layers. After the first 2 or 3 layers have been glued the insert will have been locked into shape. I would then take out the insert and glue some more layers on the inside finshing it off with some glass or carbon laminate. Maybe glue a web in there as well. Then I would glue the insert in to the mast sections (both ends) and then build up the part of the section that is replacing of cut off parts by adding more layers of ply or when it is already thick enough, adding layers of glass.

A way of making a poors mans scarve is to have the additional layers of ply on the inside reach up less far inside to old mast sections then the previous ones. This way you get a starecase like scarf. Of course this whole approach rest on using thin ply sheets and being able to steam them properly into shape. I heard from Phill that such sheets can be shaped with a blow drier as well. I would just test this and see of spraying some water before blow drying helps to shape these thigns

In the way of strength, we must not underestimate this composite of thin layers of ply. Before glass and other high tech fibres came along they used this veneer method to build life rafts. The advantages were, lightweight and yet strong construction and it would remain water tights and dependable even when stored for long times in dry places. This method was not used in a much wider sense (except for some race boats) as the labour involved for building a full boats was quite alot.

I will say one thing for the position of the damage. It is in quite a good place. The stresses and bending are pretty low on that spot. Meaning that you ca't really screw up on the repair or the bending of the mast. You have the liberty to induklge yourself in some "better save then sorry": reinforcements of the damaged area without worrying much about affecting overall behaviour of the repaired mast in the way of sailing.

I would just "risk" repairing it. And I'm not the most handy guy with laminates. Seems very doable for a reseanable handy person without the need to maintain tight margins. It seems like a rather cheap job as well. It is mostly labour. And you'll most likely end up with the right mast/sail combo again. Buying a new mast is an option you can always persue later when somehow everything fails.

Wouter

Posted By: bvining Re: Mast Repair - 04/12/06 02:28 PM

Dave,

Where are you located?

I would absolutely fix that mast. The repair technique Wouter described sounds like it will work. Create an insert out of 1 or 2mil ply - run it beyond the break on either side, stair step an extra ply up near the middle of the break. Dont overdo the strength of the repair, you dont want to create a hard spot in the mast.

The only part of his advise I dont agree with is horizontal loops of carbon uni. This really doesnt do much to reinforce the mast along the length of the mast, it would keep the wingmast section in its section and not allow it to deform, but I'm not sure that adds much to the mast, and thats not how it broke, it broke pretty cleanly in the horizontal plane, so you need to run reinforcements vertically.

I'd sand off the eglass or half the eglass and add a layer of 5.7 oz uni, with the strands run vertically. You might want to add one layer of weave overlapping the repair. If you do add a layer of carbon weave over the repair go with some light weight fabric here, like 100g/in2. The only issue you create is that that part of the mast is going to be stiffer than the rest of the mast and might cause issues in other sections.

Posted By: Wouter Re: Mast Repair - 04/12/06 04:29 PM

The only part of his advise I dont agree with is horizontal loops of carbon uni. This really doesnt do much to reinforce the mast along the length of the mast, it would keep the wingmast section in its section and not allow it to deform, but I'm not sure that adds much to the mast, and thats not how it broke, it broke pretty cleanly in the horizontal plane, so you need to run reinforcements vertically.

The loop are indeed not a cure for all. All they do is prevent early warping of the wall itself under load. This has the beneficial effect of suring up the mast making it appear stronger. By definition it is not stronger then it was before but it will move any damage mechanism to higher stresses then before. The net result is that the mast will be more resistant against abuse and overloading.

How can I explain this better. The loops themselfs don't add any strength but they do allow the already existant parts of the mast to take higher loads/stresses before any failure mechanism results in damage. So in practical terms they make the mast stronger.

The fact that the loops themselfs don't add strength means that they also don't affect the bend characteristics much at all. This is not a side effect but fully intended property of adding the loops. The mast design will behave as before but still is it will be able to take higher external loads (gusts, sheet tensions etc) I feel we are after the last thing.

Most masts do not fail because of some stress exceeding some maximal material property, but rather because the masts enter into a instability failure mode. Buckling is one such example. The material should be able to handle the buckling loads quite well but the fact that it bends out of colom seriously lowers the stresses at which damage occurs.

I feel that with this mast the instability failure modes are to blame for the damage and not the mast strength per see, the damage is not in a particulary highly loaded spot. Suring up with loops seems like an attractive option in this situation.

But I fully admit that adding loops is optional

Wouter

Posted By: bvining Re: Mast Repair - 04/12/06 05:39 PM

Wouter,

Is that what think happened to this mast? That the walls warped and the section failed?

So if you are correct in saying

but rather because the masts enter into a instability failure mode. Buckling is one such example. The material should be able to handle the buckling loads quite well but the fact that it bends out of colom seriously lowers the stresses at which damage occurs

then I would recomment a sanding off the eglass and replacing it with one layer of 5.7oz weave carbon - it will resist both warping and bending failures much better.

Posted By: bvining Re: Mast Repair - 04/12/06 05:58 PM

Dave,

Building a carbon wingmast would be easy if,

1. you knew the tolerances to build it to and

2. you had a wingshaped male mold.

You can get a good catamaran architect to tell you (you would probably have to pay him) the layout of the cloth and how many layers and how to orient them and such. Applying the cloth is the easy part.

The hardpart in my opinion is the male mold.

You could make a male mold out of lightweight foam and wrap it in carbon.

You could make a light weight ply section like the one you have any wrap it with carbon.

You could make the male mold out of machined polished aluminum and wrap it in carbon and remove it, but by this point you'd be in the mast building business.

I'd say it would be easier to fix the one you have an wrap it in carbon to make it stronger.

Bill

theoriticly you would not want to use carbon because of the different flex characteristics it has compared to the rest of the mast. there is a good chance it would work anyway tho.

kevlar has about the same flex characteristics of glass...if you use kevlar burry it deep under glass because it cant't be feathered down like glass or carbon. epoxy, s-glass, and wood should be good repair materials for the job. consider radiating the fibers of the cloth rather than lining them all up in the same direction. you may not be able to put enough material on the inside to take the loads that run inside the mast, but it's worth a try.

for me building a mast seems a little tricky because of the mast track. i'm thinking high density foam core shaped on a cnc machine and glass it w/carbon & s-glass. then gluing the track on with urethane glue. the track could maybe be a tube that has a groove cut into it.

sound realistic?

Posted By: basket.case Re: Mast Repair - 04/12/06 11:11 PM

Dave,

Building a carbon wingmast would be easy if,

1. you knew the tolerances to build it to and

2. you had a wingshaped male mold.

You can get a good catamaran architect to tell you (you would probably have to pay him) the layout of the cloth and how many layers and how to orient them and such. Applying the cloth is the easy part.

The hardpart in my opinion is the male mold.

You could make a male mold out of lightweight foam and wrap it in carbon.

You could make a light weight ply section like the one you have any wrap it with carbon.

You could make the male mold out of machined polished aluminum and wrap it in carbon and remove it, but by this point you'd be in the mast building business.

I'd say it would be easier to fix the one you have an wrap it in carbon to make it stronger.

Bill

make a quick easy FEMALE mould. it is the only way to do it. the engineering is easy. the mast track is easy. dont get worked up because it is a mast.

i snapped an aluminium spar and had no option but to build one. i threw a glass mast together with a bit of help in a weekend. cost me about $200 canadian and lasted for four years.

i am not saying that this should be done here, but it is an option that should be explored.

Posted By: davidtilley Re: Mast Repair - 04/13/06 01:52 AM

I wish I could find some info on the "elastic modulus" of wood.

I see the design problem with wood/glass (and even more so carbon/glass) being that you are expecting the wood to take the compressive load and the glass the tensile, which really can't happen efficiently. The glass skin will be buckled way before the wood is loaded up to failiure. However, In Reality, the wood supports the Glass laterally to prevent local buckling,(Like the rings Wouter wants to add?) and allows the glass to take compressive load. Can anyone come up with some numbers?

I suspect therefore that the glass/wood mast is not that much better than an epoxied wood mast. (In other words, the wood is probably typically able to handle enough tensile load to crush itself on the opposite side, and so you are essentially adding glass to do a job it is not particularly suited to, unless sandwiched or honeycombed to resist local"surface" buckling.

To return to the original question: Maybe it would shed some light to imagine the mast having failed by the glass skin first failing on buckling, and the fibres breaking, while none the less the wood kept the mast up. Going onto the opposite tack, the glass fibres parted in tension. The wood typically would not be asked to take this tensile load, because the glass skin is so good at it, and the design may not have intended it.

Posted By: davefarmer Re: Mast Repair - 04/16/06 05:52 AM

OK boys, here's the latest. My buddy Joe Poire, who races (and breaks!) I14s regularly, stepped up and said "lets fix it' now big deal". Spliced it in much the fashion recommended above (Wouter?), wrapped the break in carbon weave, then a 30" wide glass weave. 3 guys, 7 hours, a heat gun, and a fair amount of beer, and I once again have a one pc mast. Still in debate about whether to throw it up again and watch it closely, or laminate one layer of carbon uni from base to hounds (which I'm leaning towards).

Upon completing the repair, we walked the mast out to the trailer and set it in the cradles. Turns out the repaired break landed directly on the support cradle, which generated the suspicion that the mast may have been damaged at some time while in transit at some point (I trailered the boat from SF to WA last Nov, don't know how much travel it saw before me). There wasn't any damage visible on the outside of the mast, but the base is quite heavily reinforced around the foot and gooseneck, so maybe this extra weight hanging some 6' aft of the mast cradle and bouncing around over some thousand miles created some damage or stress internally. I don't know, a bunch of theories have been posited here, several quite detailed and most believable, often conflicting.

I'm very grateful to all of you for all the advice, education, and offers of replacement masts. I'll keep you posted as to whether she stand tall.

Dave